Details

The Re-Wet Agglomerator System designed and supplied by Evaporator Dryer Technologies, Inc. for Wisconsin Specialty Protein is a comprehensive and sanitary processing unit intended for agglomerating protein powders such as WPI-90 and WPC-80. Its main function is to enhance the solubility, flowability, and functional characteristics of fine protein powders by rehydrating and binding them into larger, more manageable particles through a precise re-wetting and drying process.

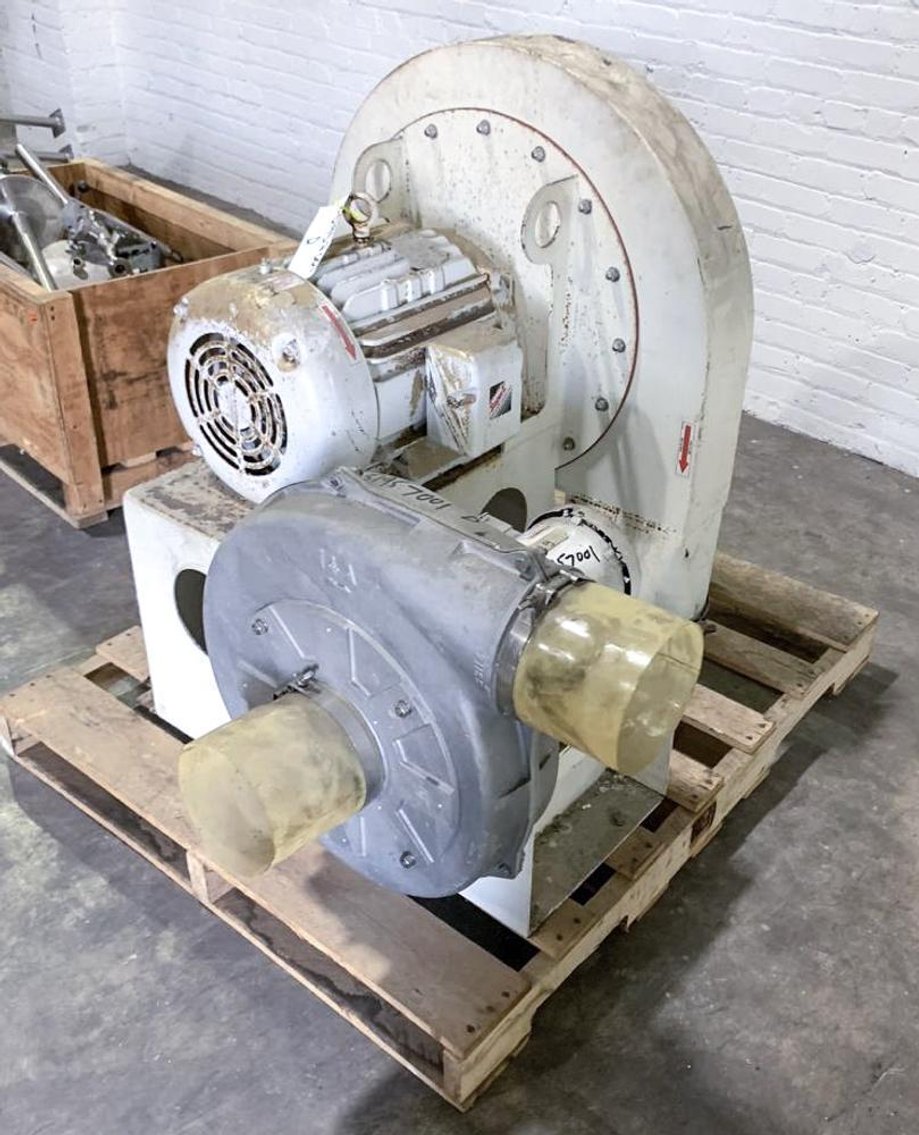

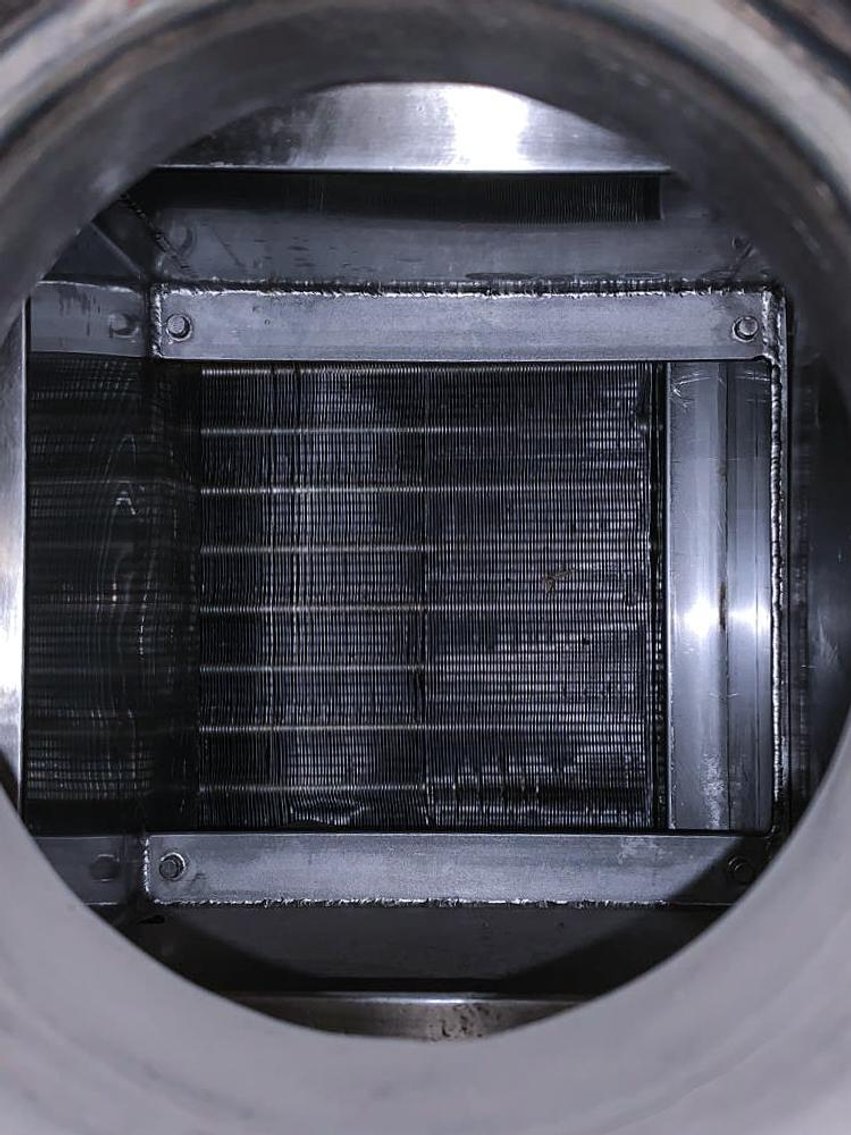

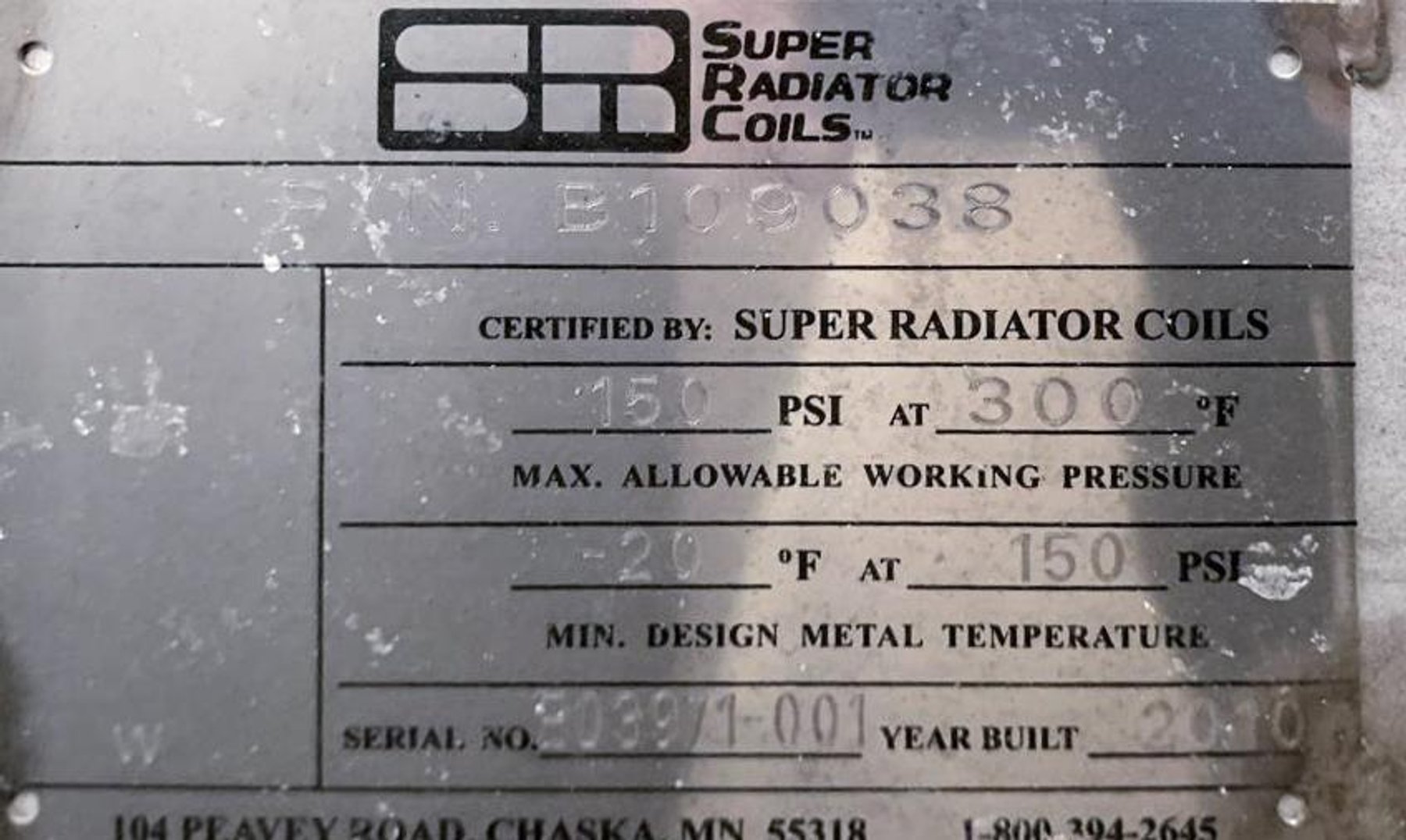

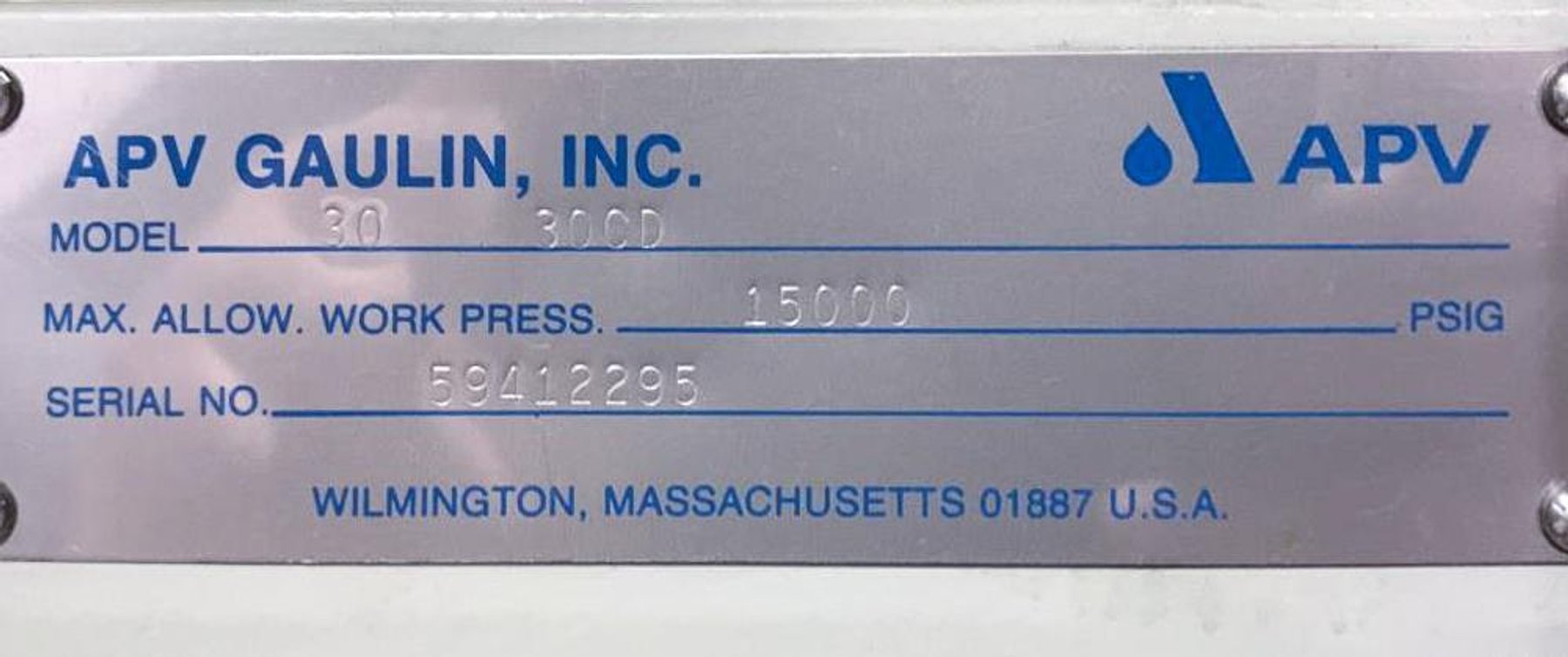

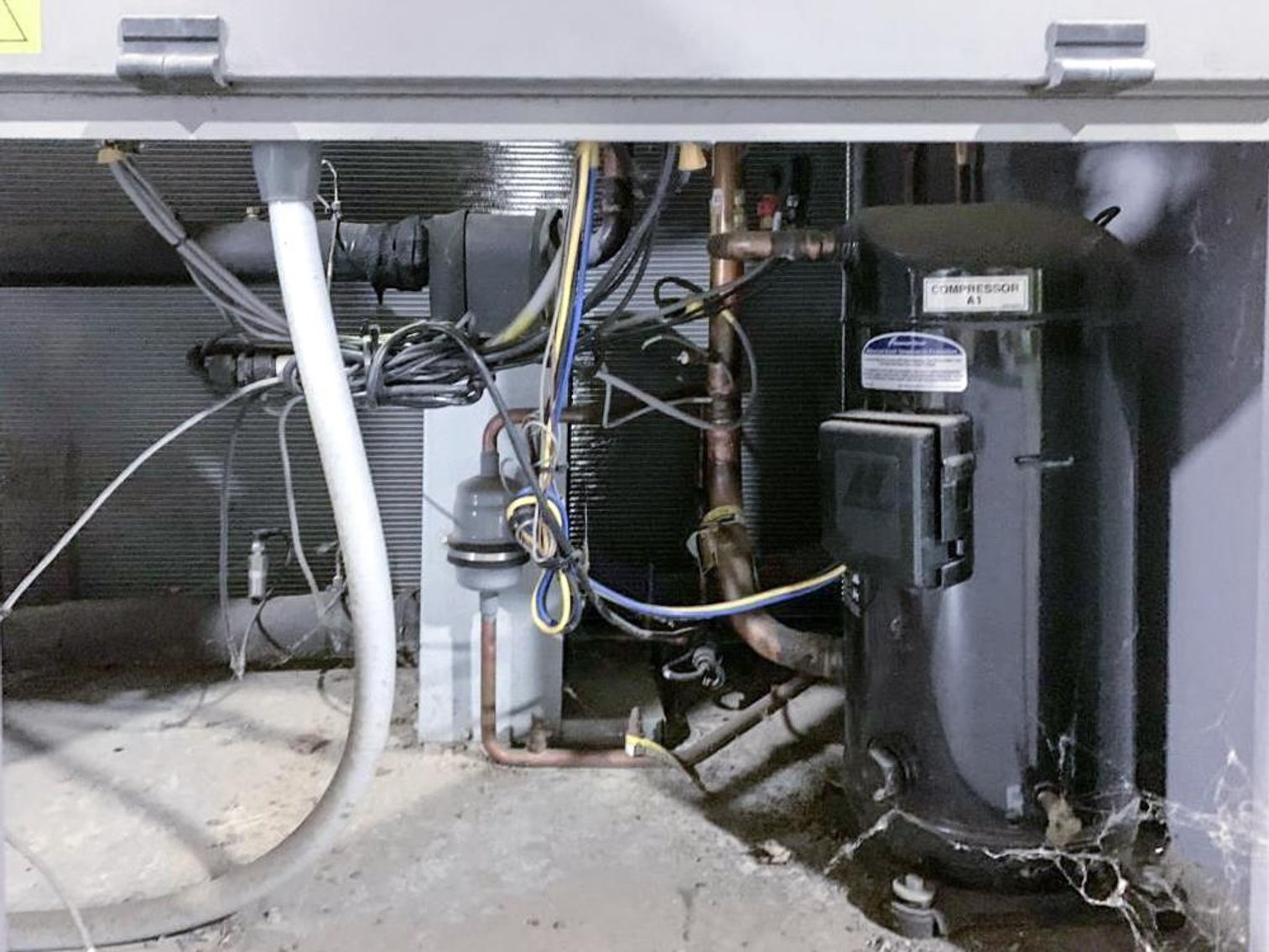

The system begins with a screw-type feeder that introduces the dry product into the agglomeration line, where a high-pressure pump injects a fine mist of heated liquid into the powder stream within a stainless steel re-wetting chamber. This forms agglomerates, which are then processed through a multi-zone drying and cooling section comprising an integrated fluid bed and a three-zone vibrating fluid bed dryer. These components are designed to condition, dry, and cool the powder using filtered and temperature-controlled air, with systems for steam heating and glycol-based cooling.

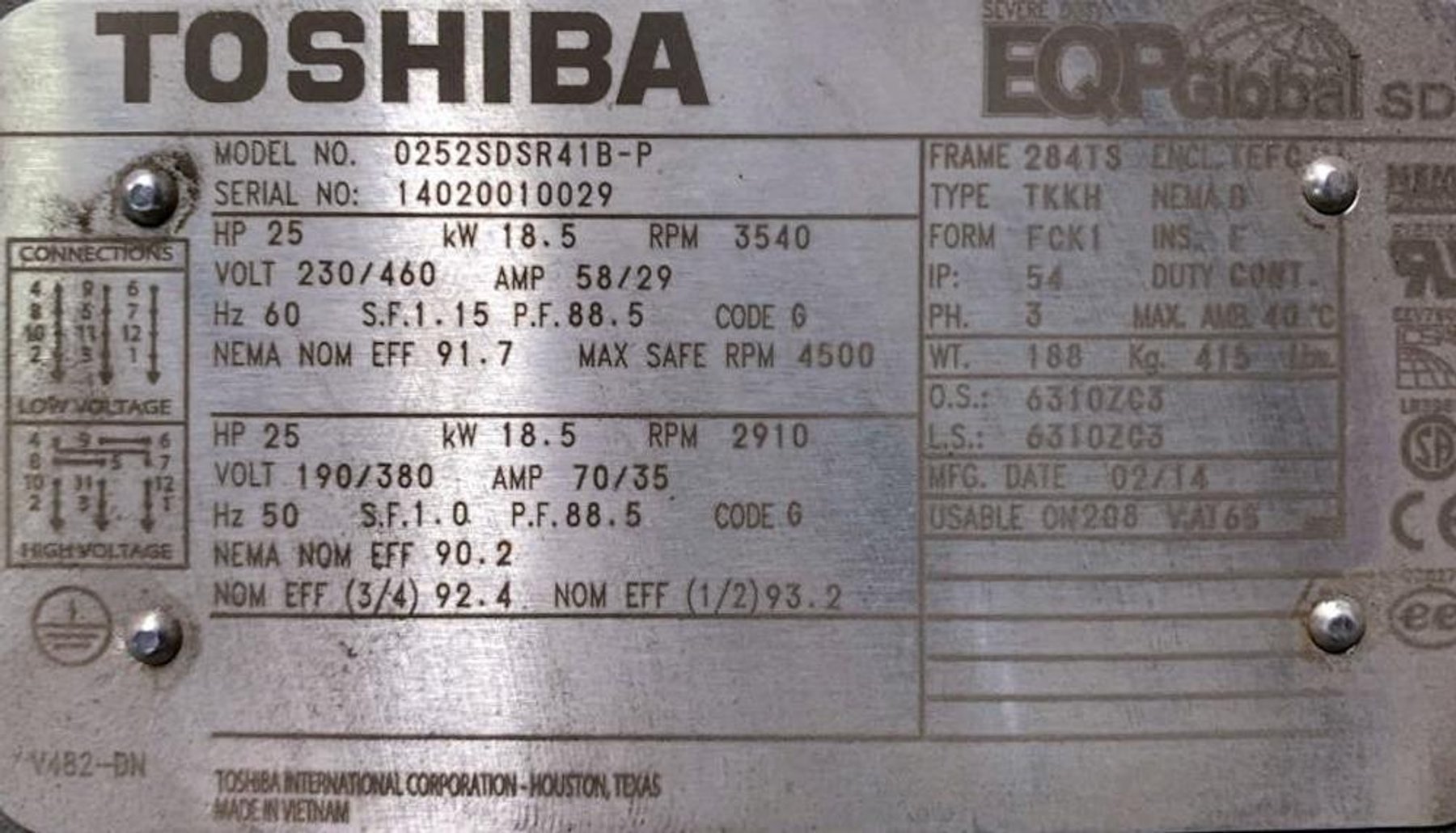

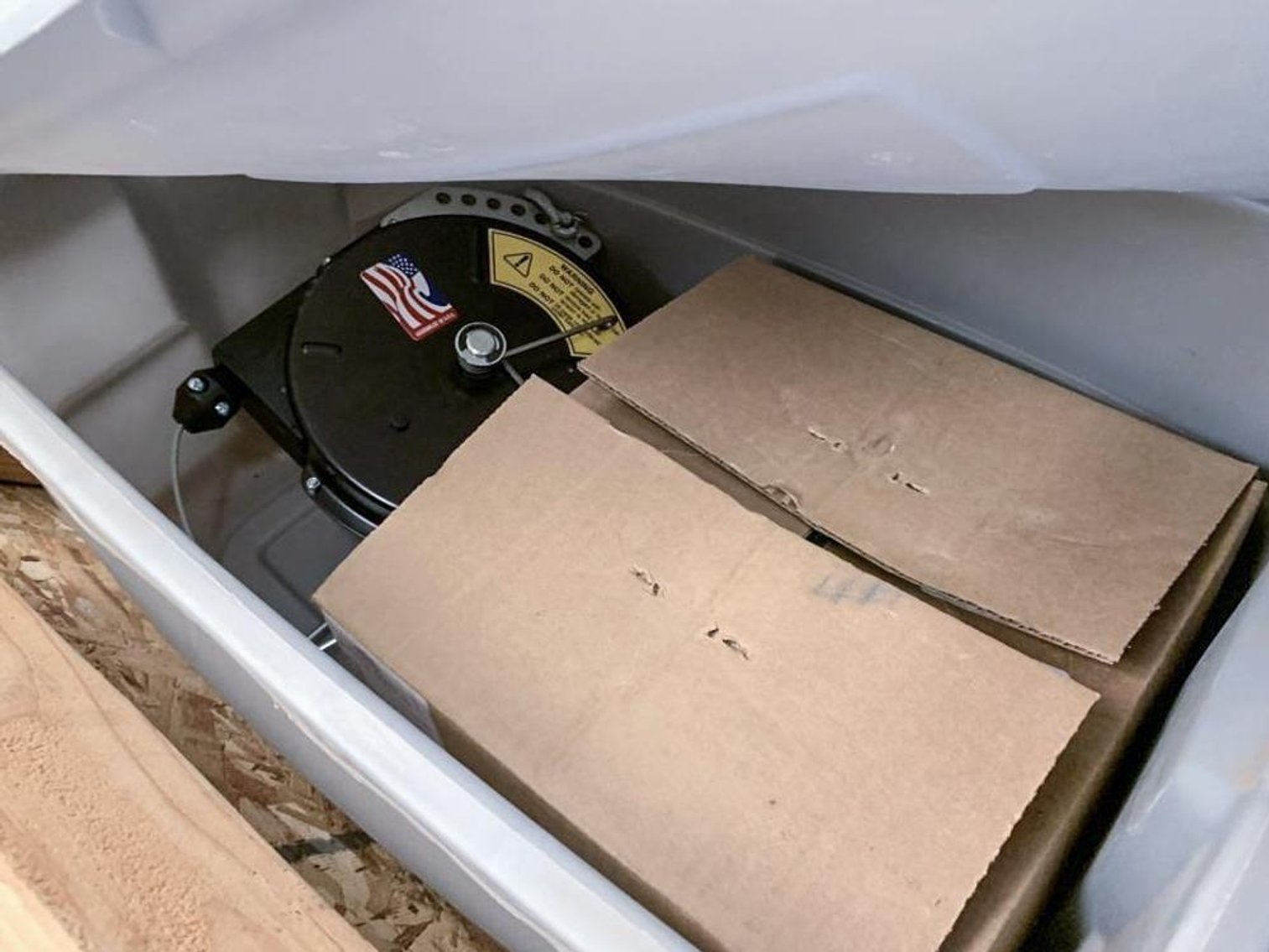

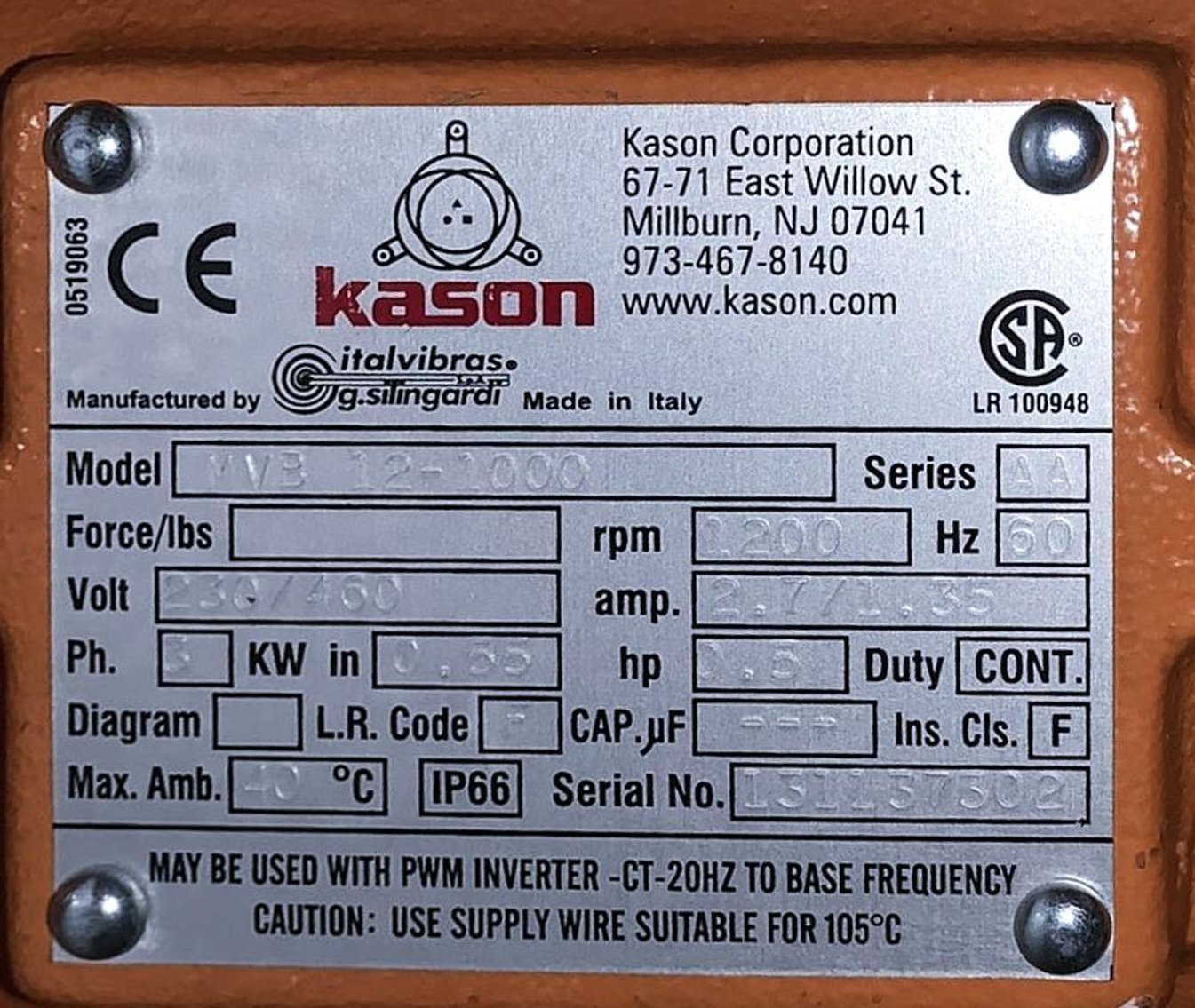

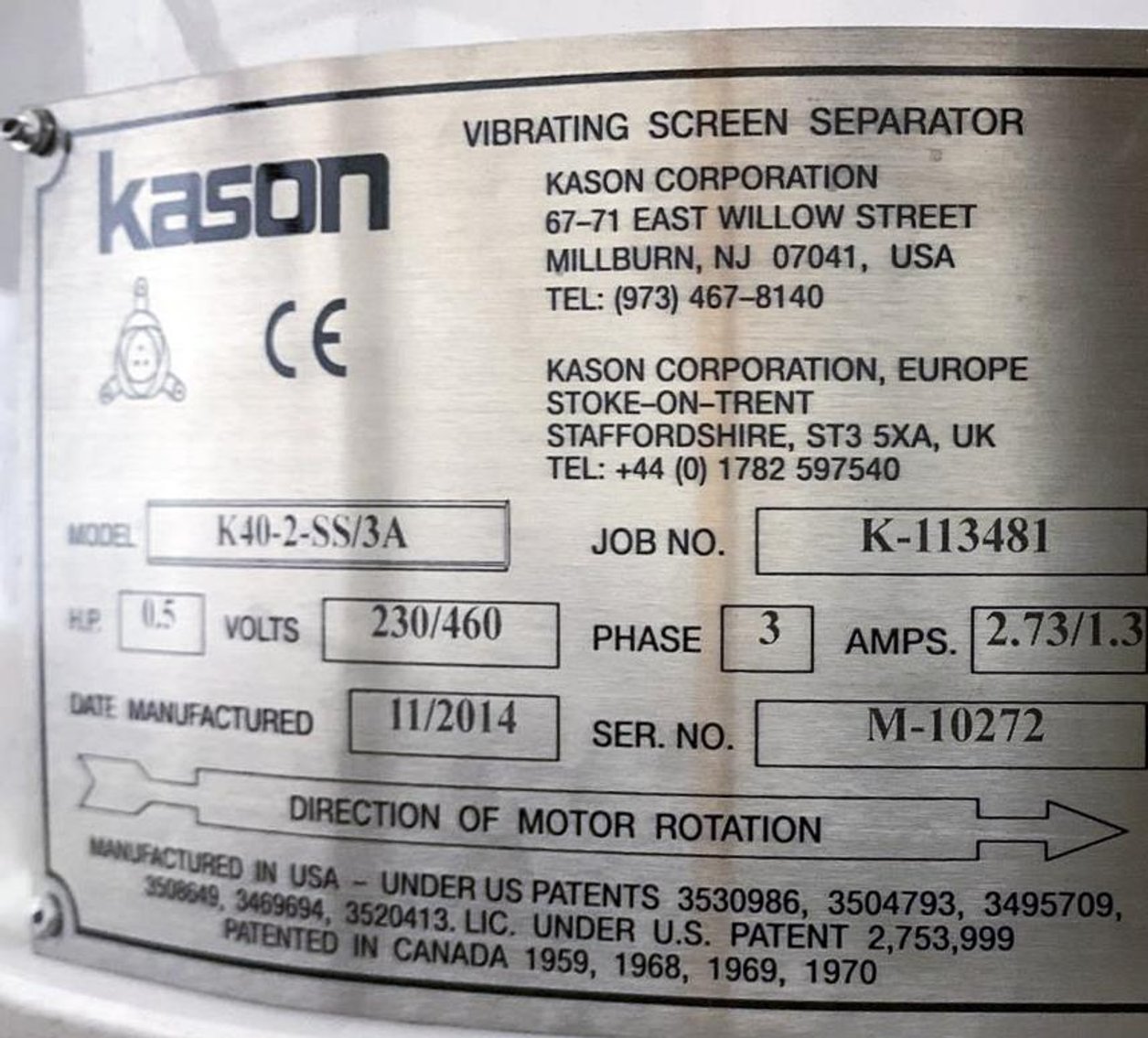

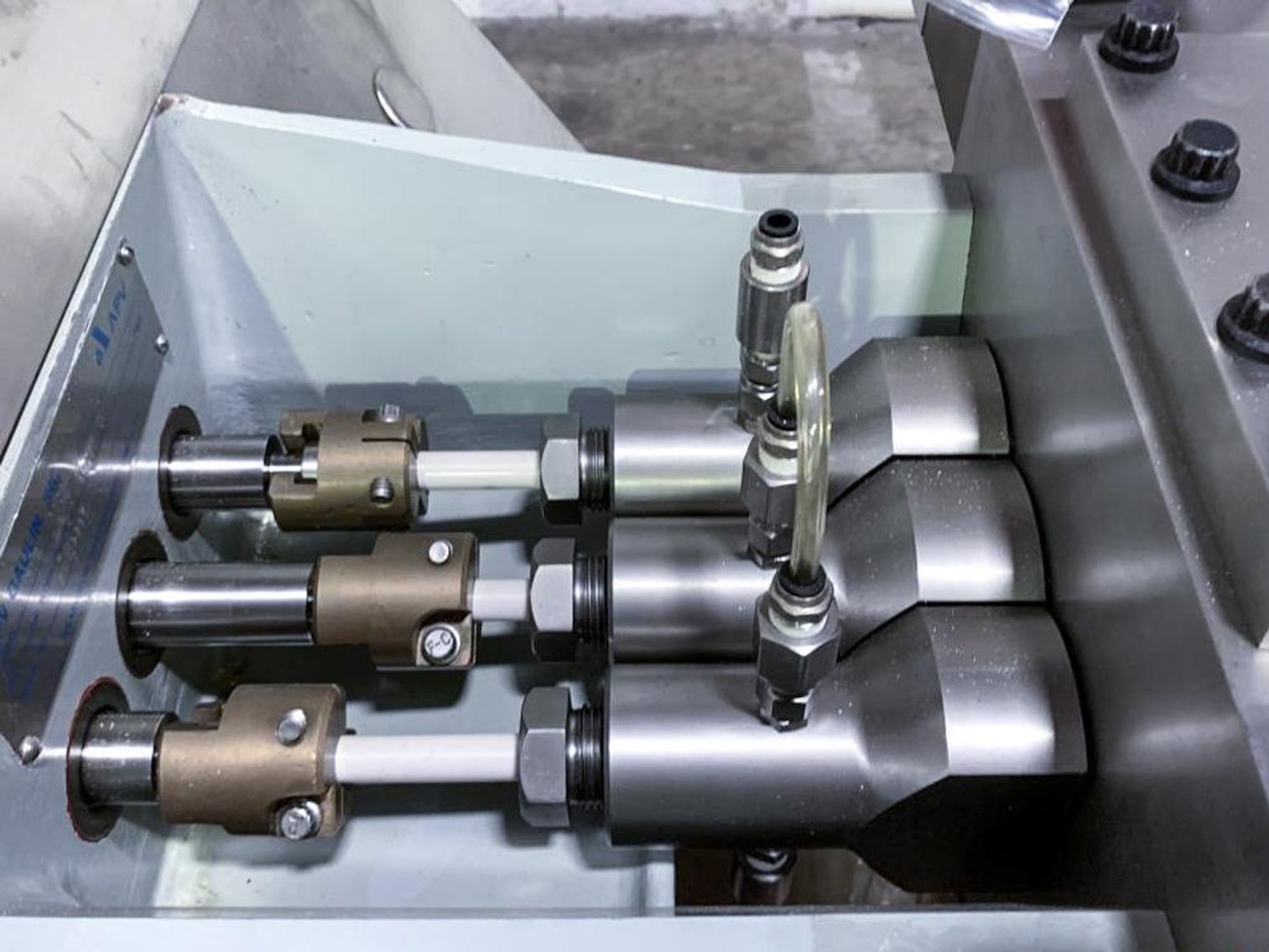

Constructed primarily from AISI 304 stainless steel to meet USDA and 3-A sanitary standards, the system includes features such as retractable CIP (Clean-in-Place) spray nozzles, a fire suppression system, and dense-phase vacuum powder conveying. Key support units include a lecithin injection system, a triple-deck sanitary sifter, dual powder receiver cyclones, and a baghouse (BGH-12) with cone heating and cyclonic separation to ensure efficient air filtration and powder recovery.

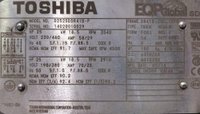

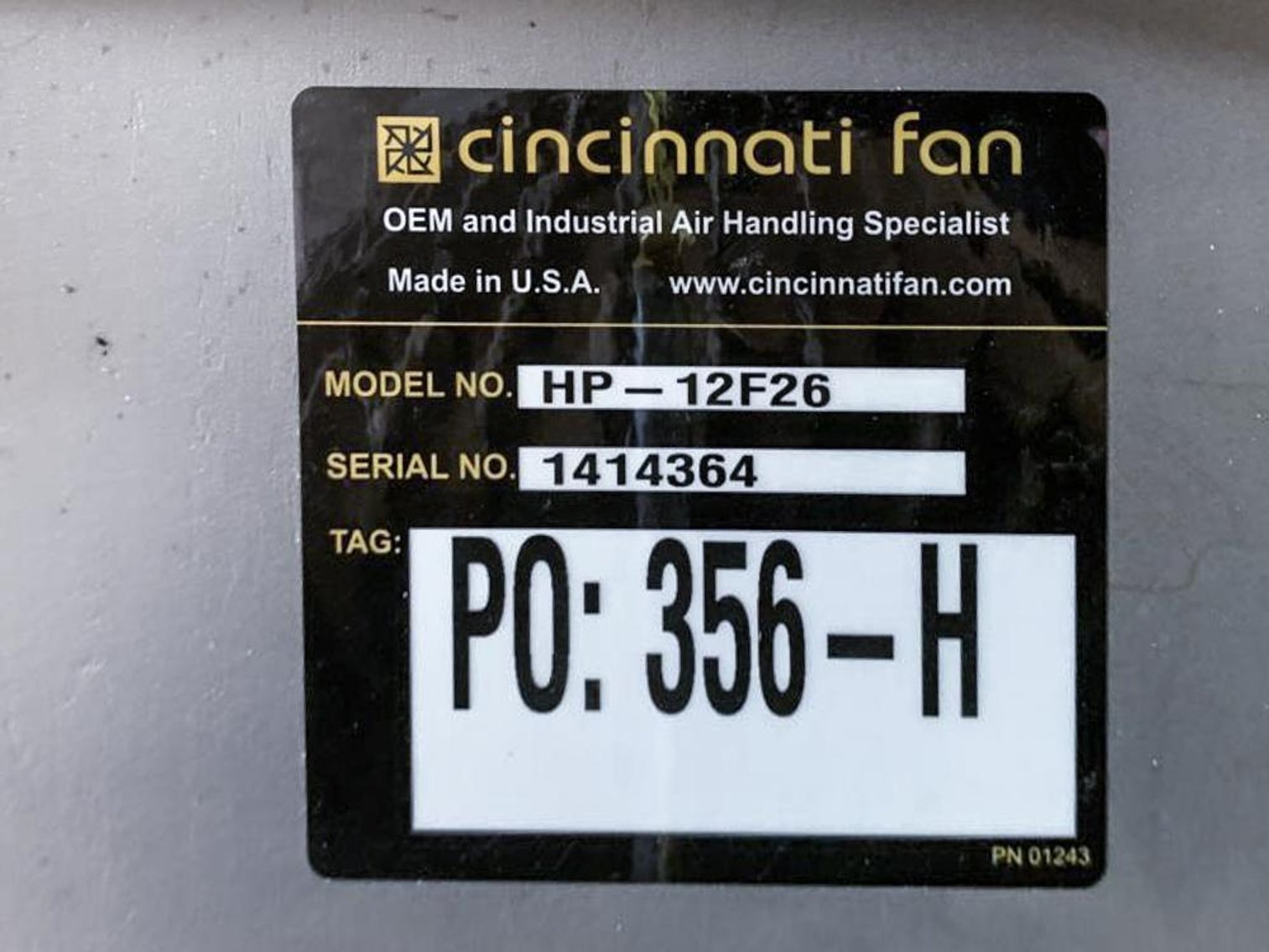

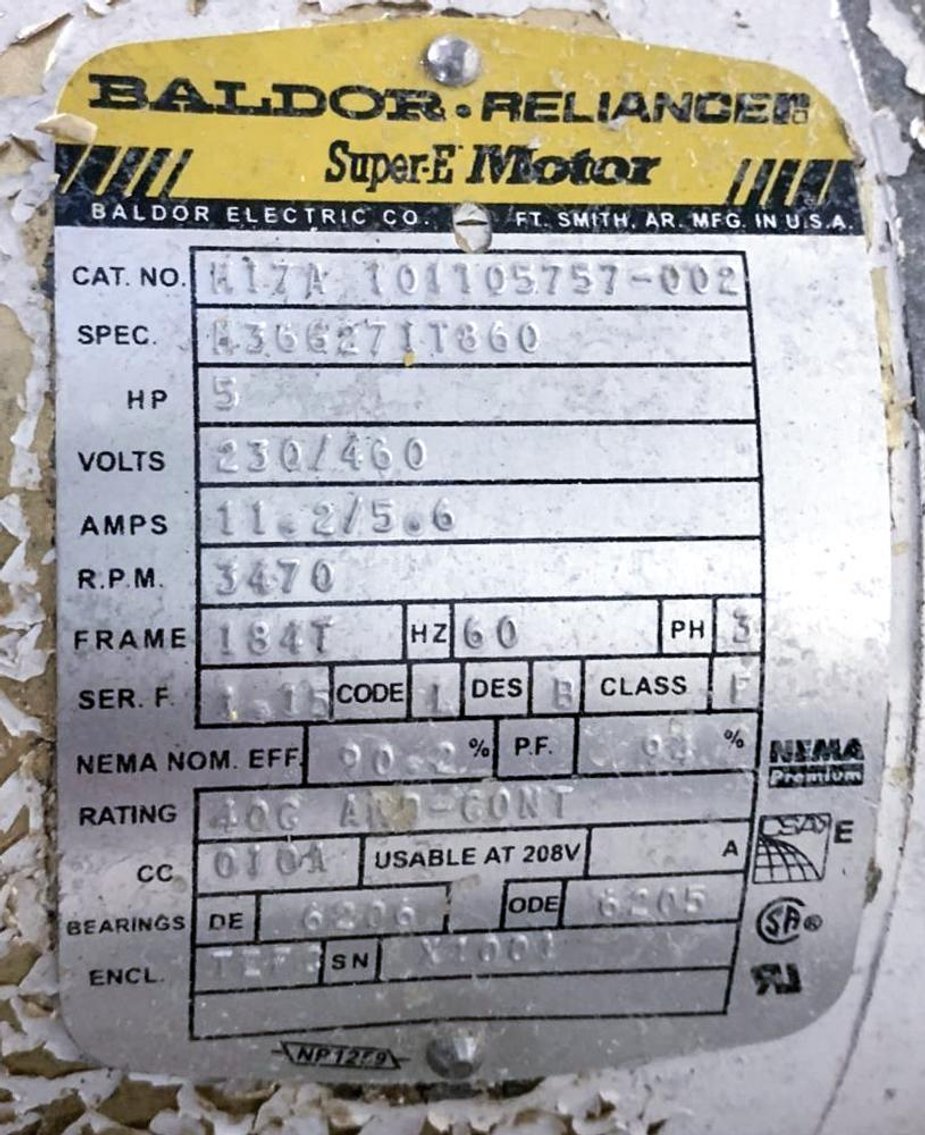

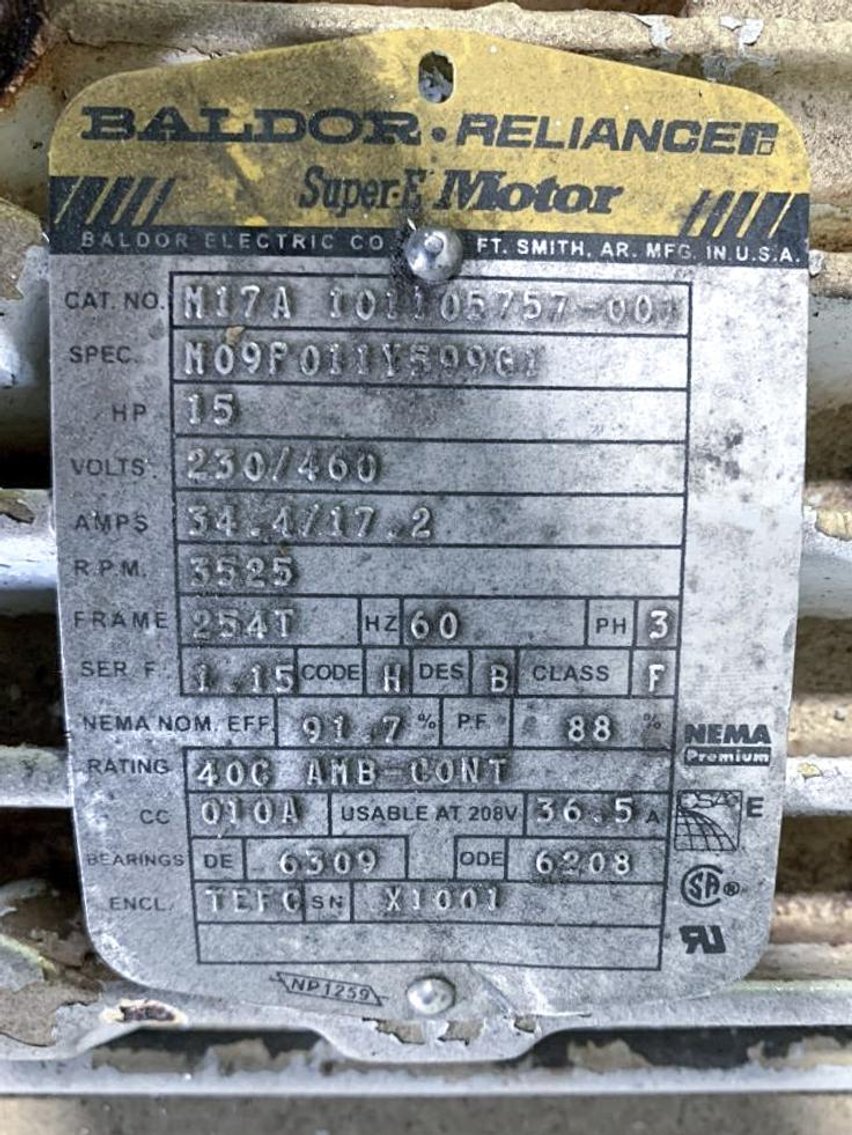

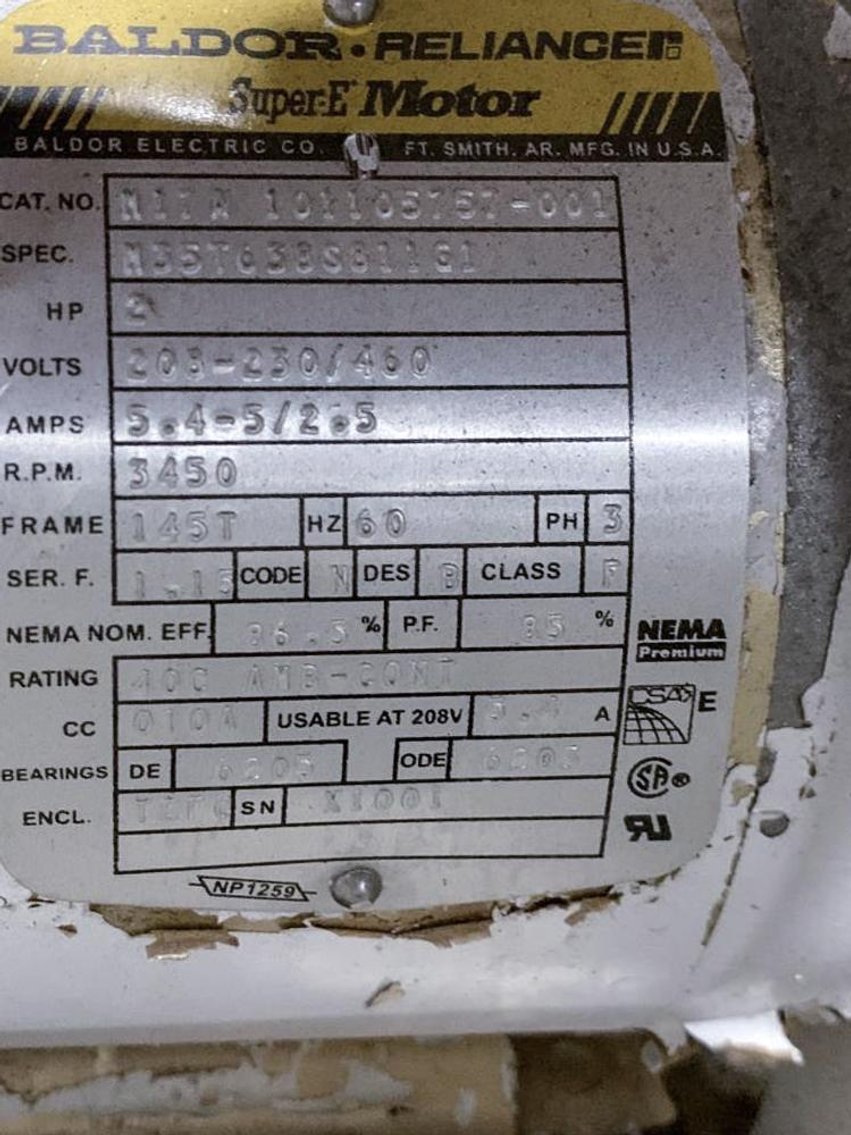

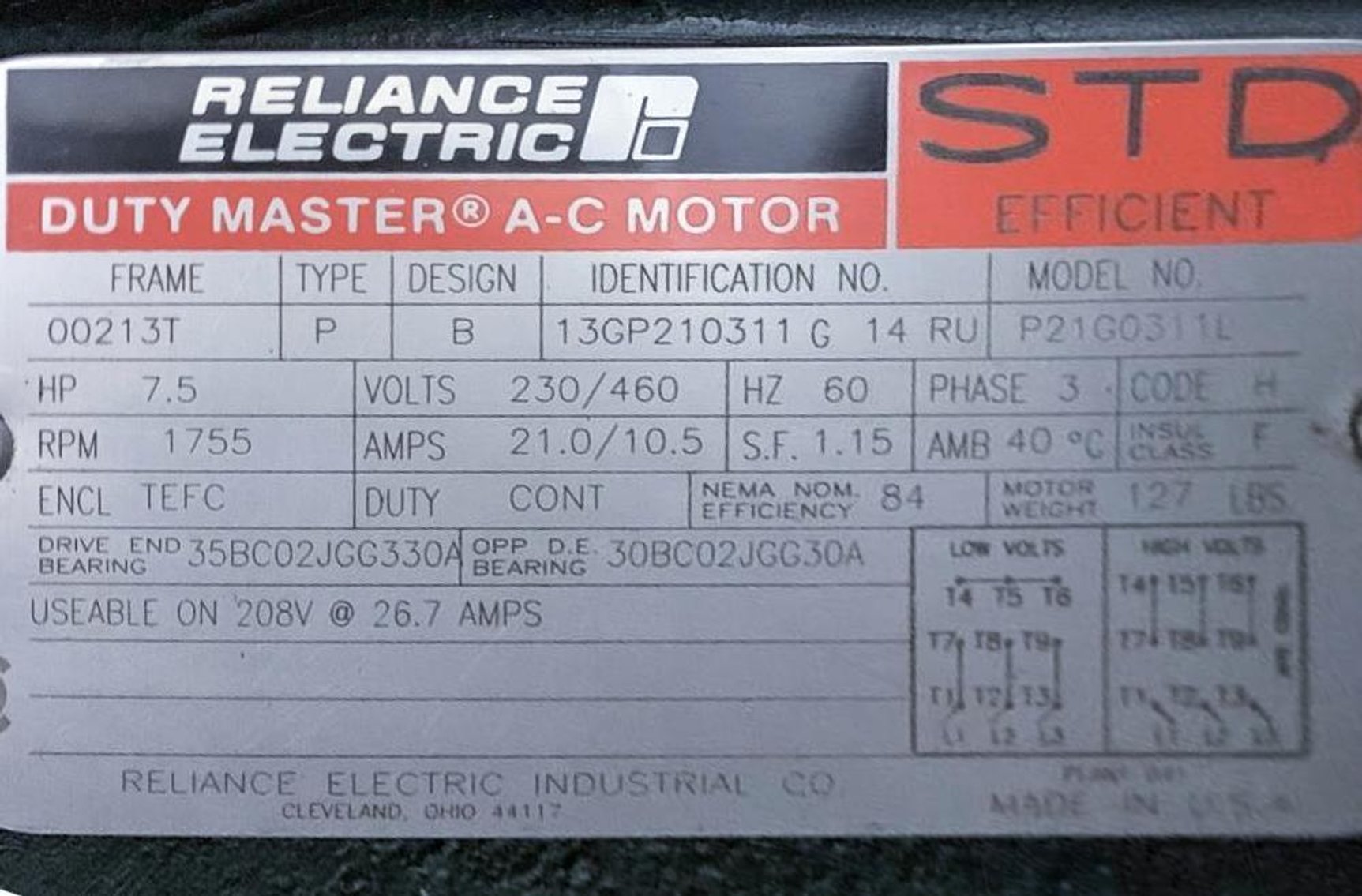

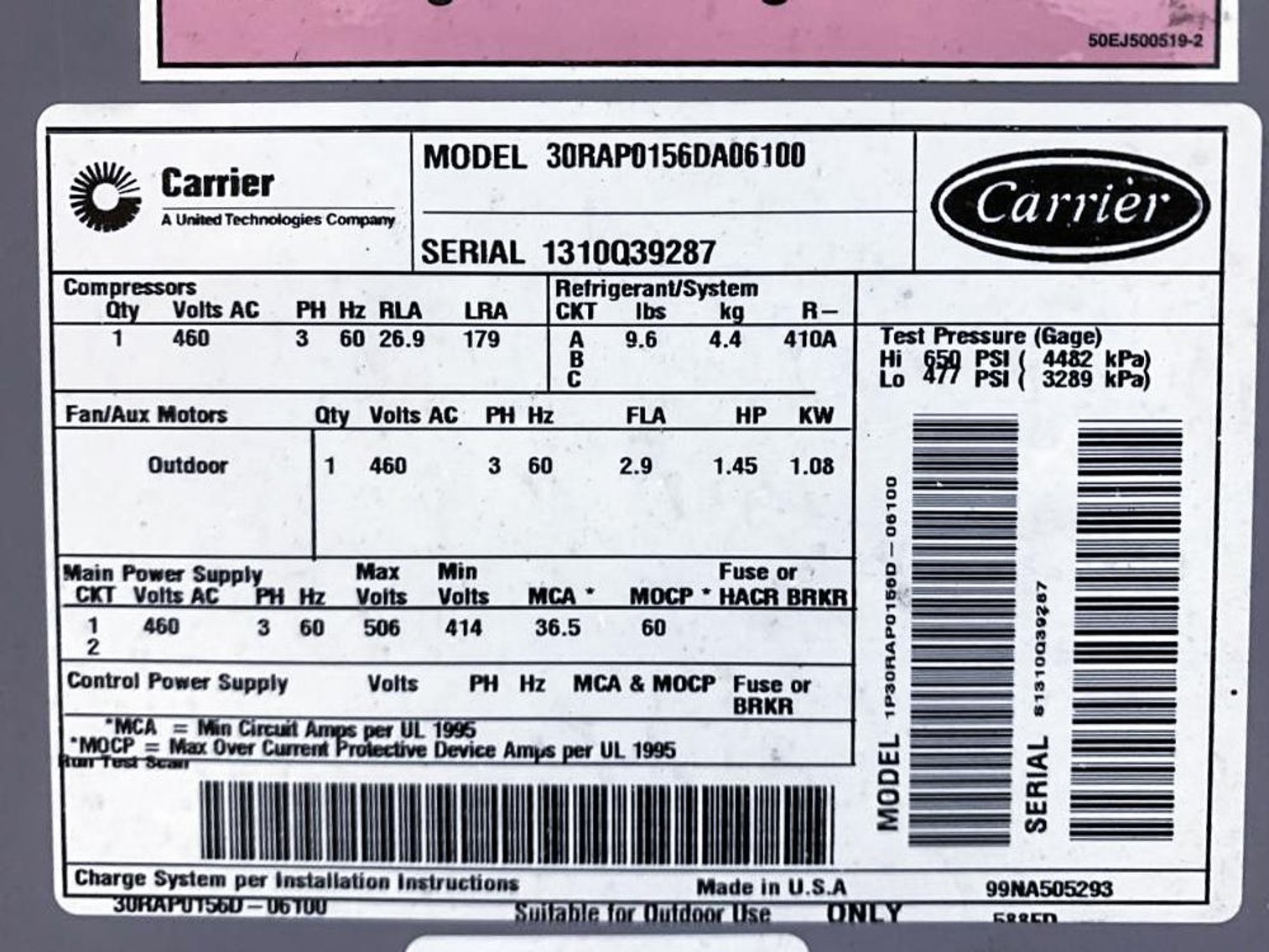

The machine is capable of processing up to 1,290 lb/hr of WPC-80 and 997 lb/hr of WPI-90, raising their moisture content from 4% to 14.4% and 17% respectively. The final powder exits at a controlled temperature of 95°F. It consumes 450 lb/hr of steam and 70 kW of power, with a total installed motor capacity of 123 horsepower. The system is designed to function reliably under varying environmental conditions, from -13°F to 90°F, at an elevation of 850 feet.

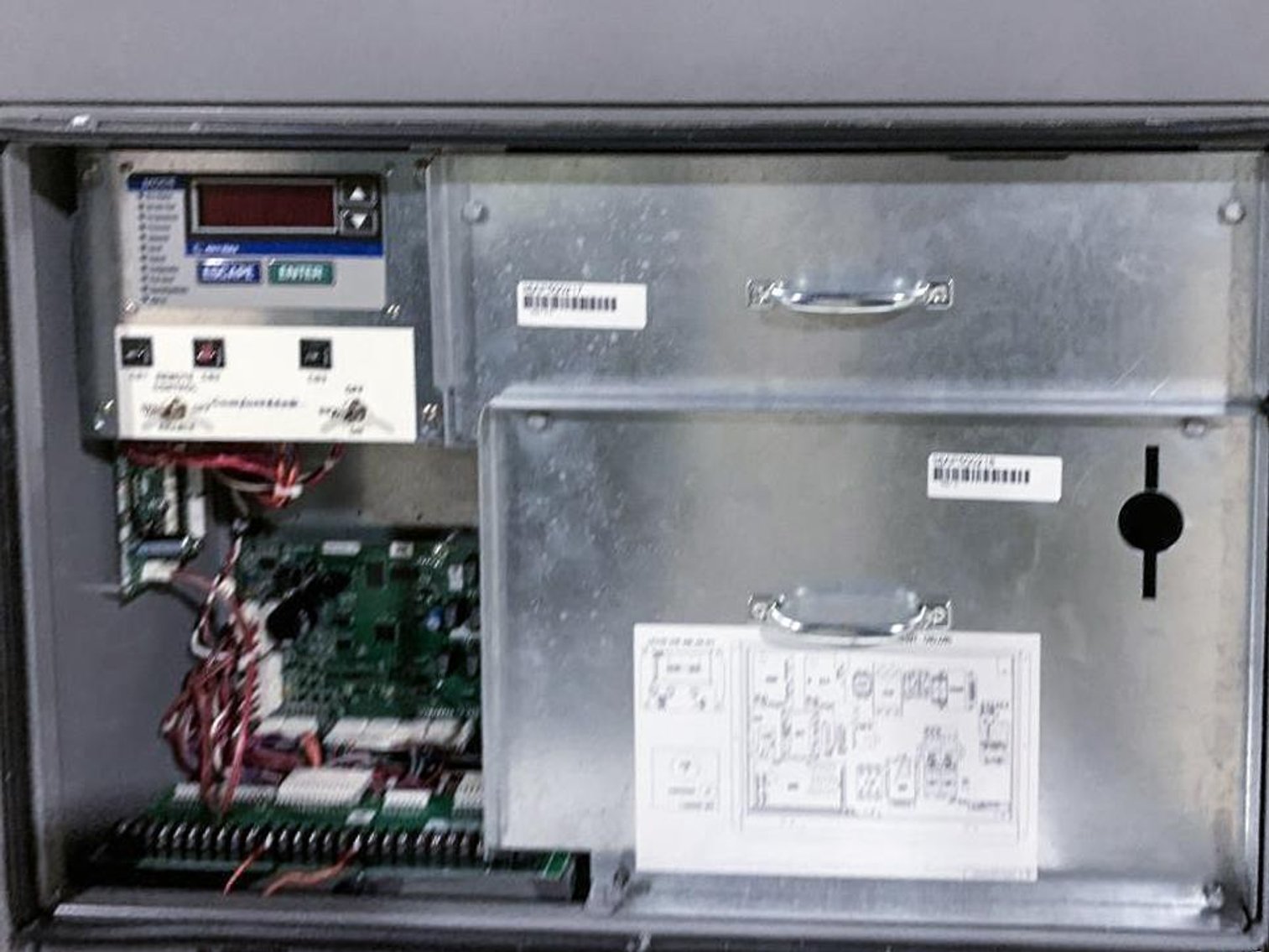

Automation and control are managed by an Allen-Bradley ControlLogix PLC system, featuring a 15-inch HMI touch screen,

In summary, this Re-Wet Agglomerator System is a fully integrated, hygienic, and high-efficiency solution tailored for the production of rehydrated, agglomerated protein powders in a food-grade processing environment.

Located: Grand Junction, CO