Details

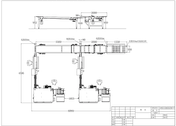

MJK2400 NEW IN CRATE Sinofude CJZ510-2 Dual-head Advanced Chocolate Production Line (with nut depositor)!

The Sinofude CJZ510-2 Dual-head Advanced Chocolate Production Line (with nut depositor) is a versatile solution designed for the production of single-color chocolates, dual-color combinations (left and right or top and bottom), and centrally filled chocolates.

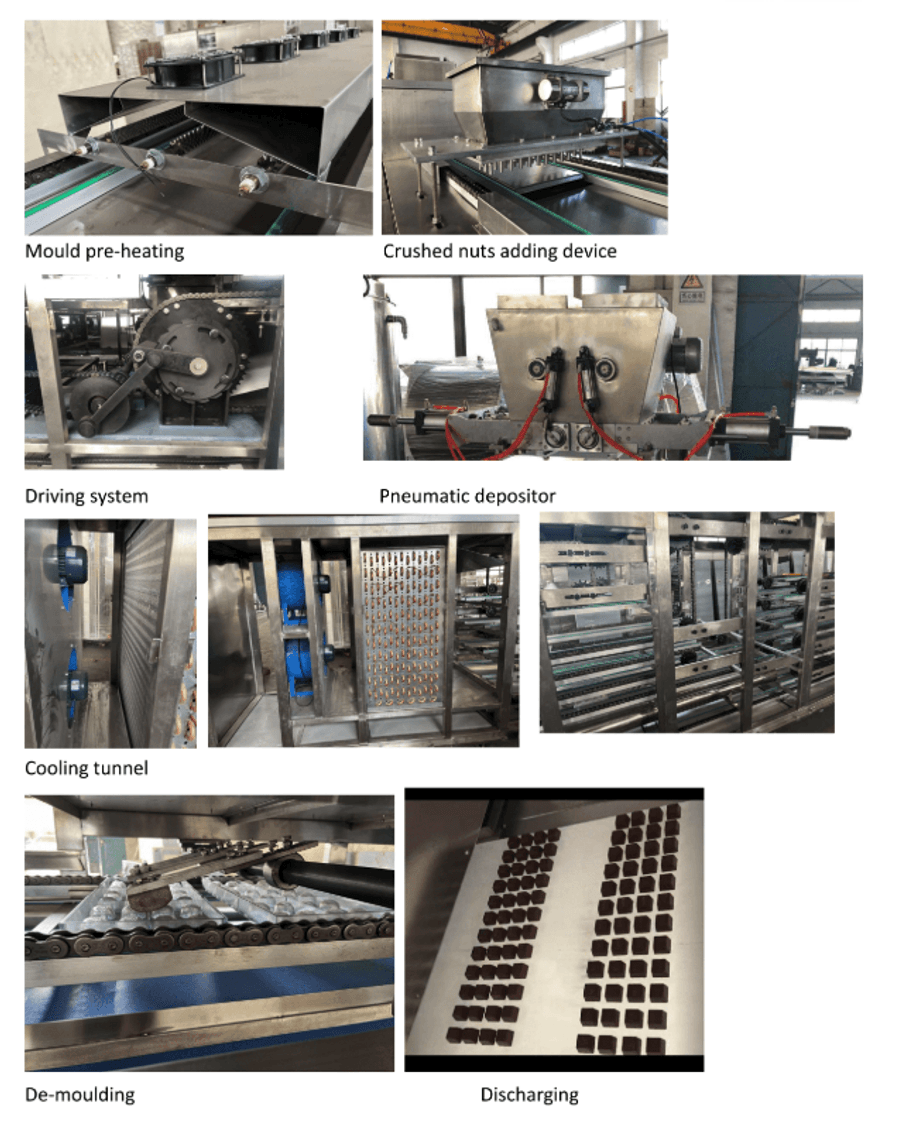

This fully automatic system features:

Mould pre-heating

Dual depositing cycles

Dual mould vibration

Dual-stage cooling

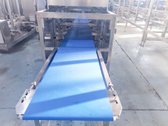

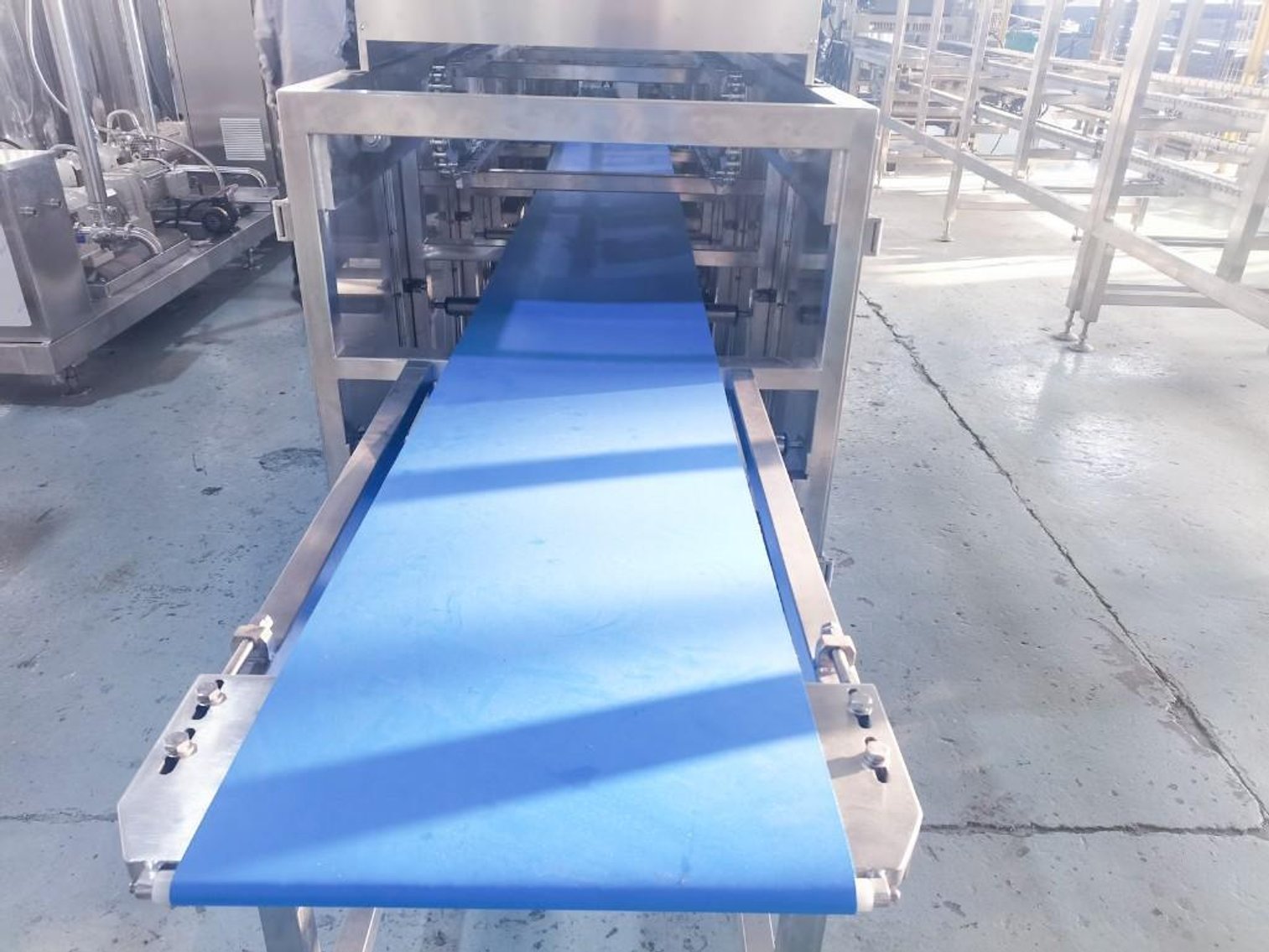

Automatic de-moulding and conveying

PLC control system, ensuring precise operation and consistent product

quality.

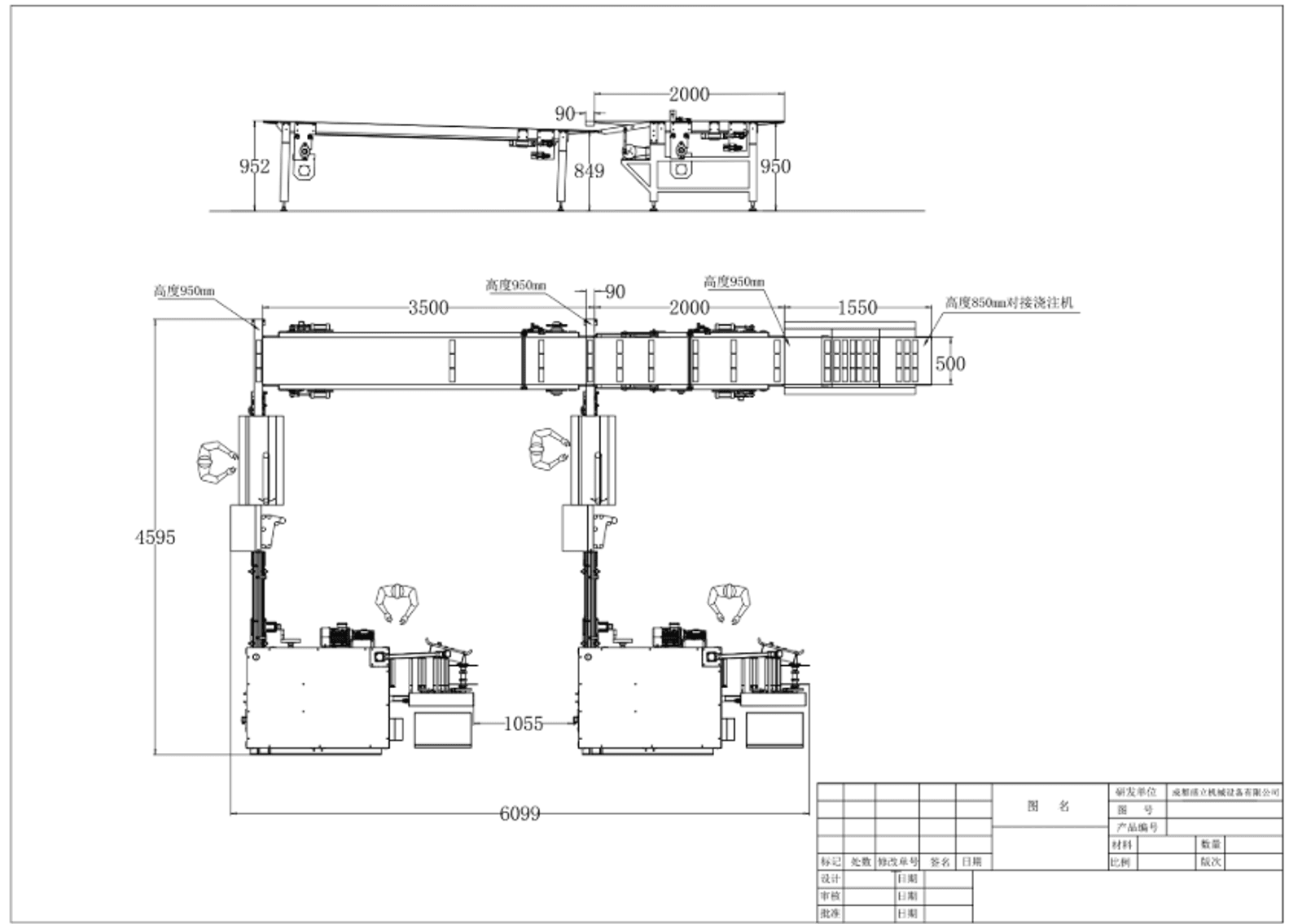

The CJZ510-2 Dual-head Chocolate Production Line consists of the following pieces:

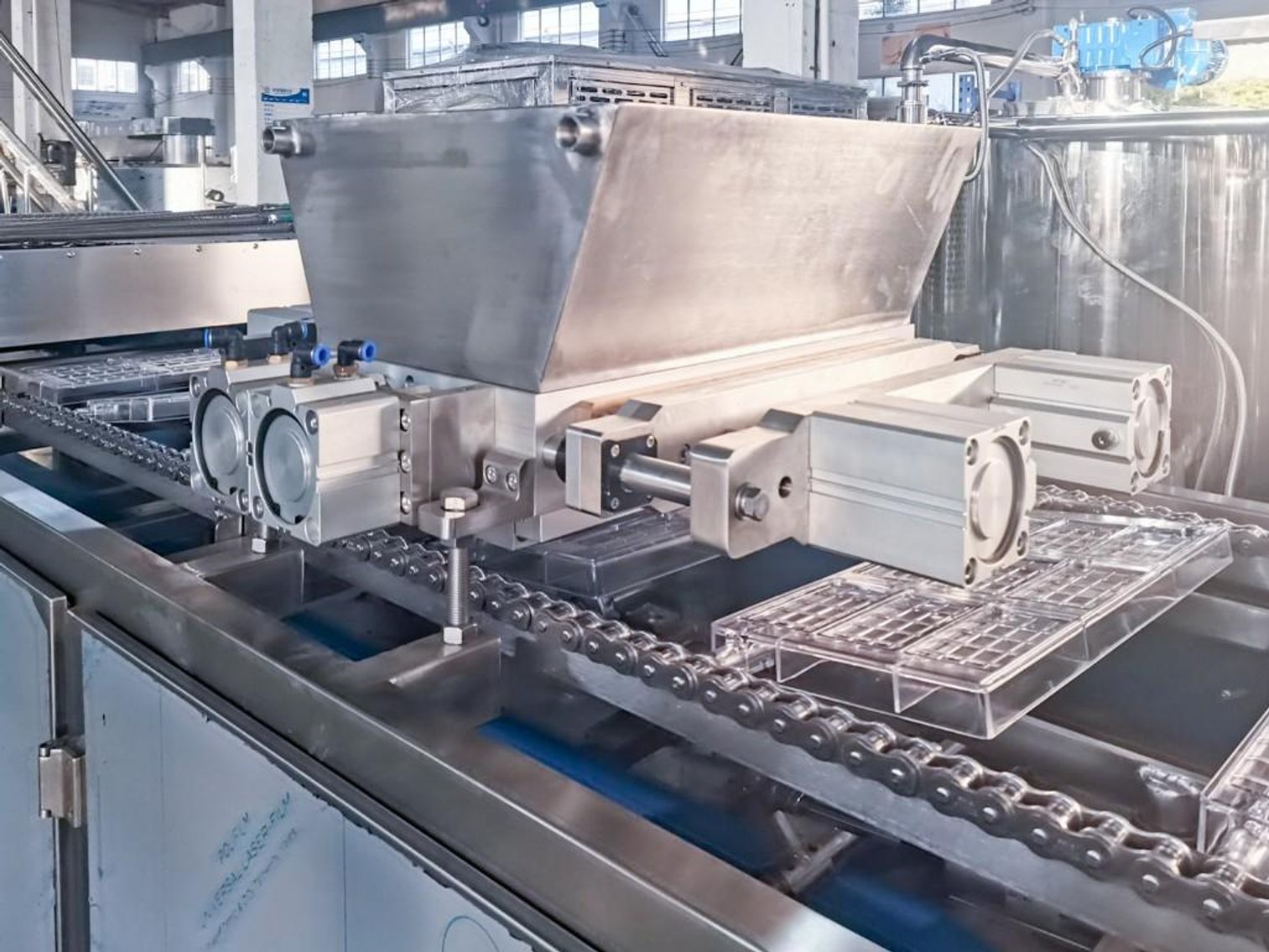

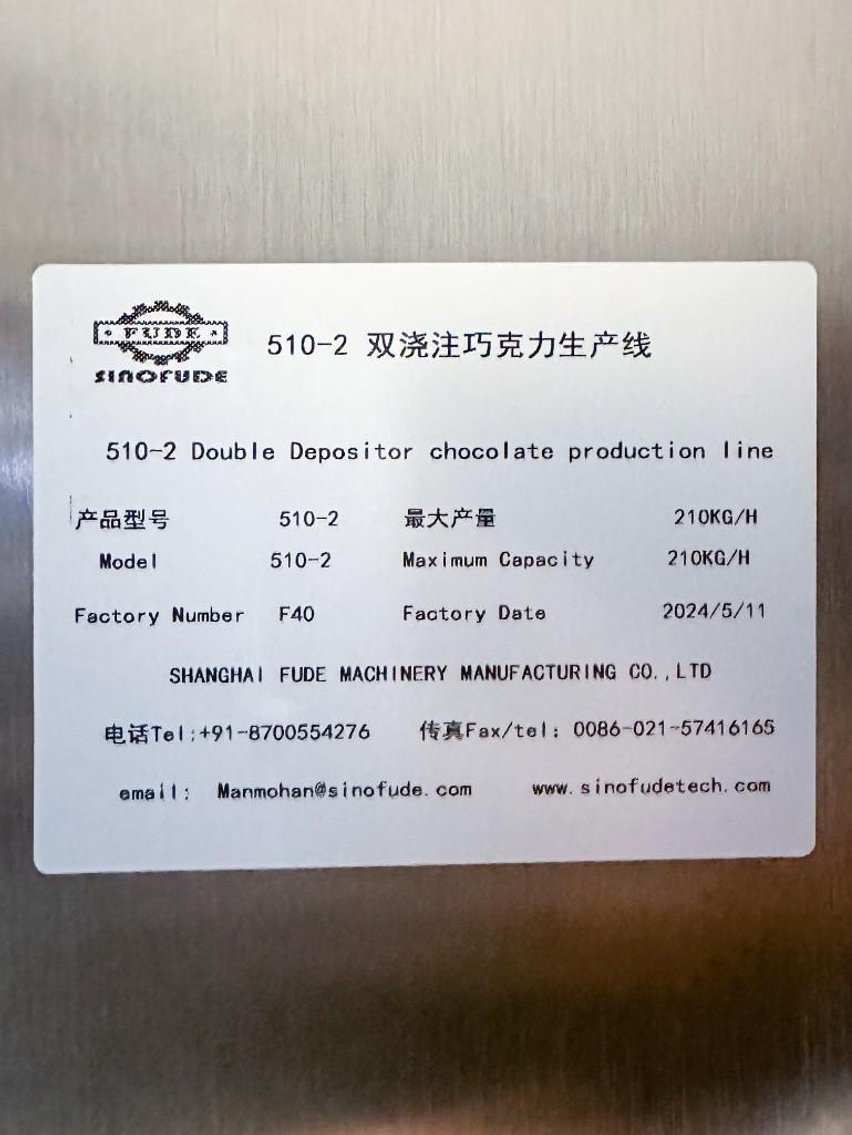

CJZ510-2 Dual-head Chocolate Depositor

Model: 510-2

Capacity: 210KG/H

Serial Number: F40

MFG DATE: 2024/5/11

Product hopper with stirring system (2 sides for 2 different chocolate pastes)

with 1 water temperature control system.

Depositing Type: Pneumatic

Depositing Head Pistons: 48 pieces per-side and total 96 pieces(both sides)

Production Capacity: 6-15 pieces of moulds/minute

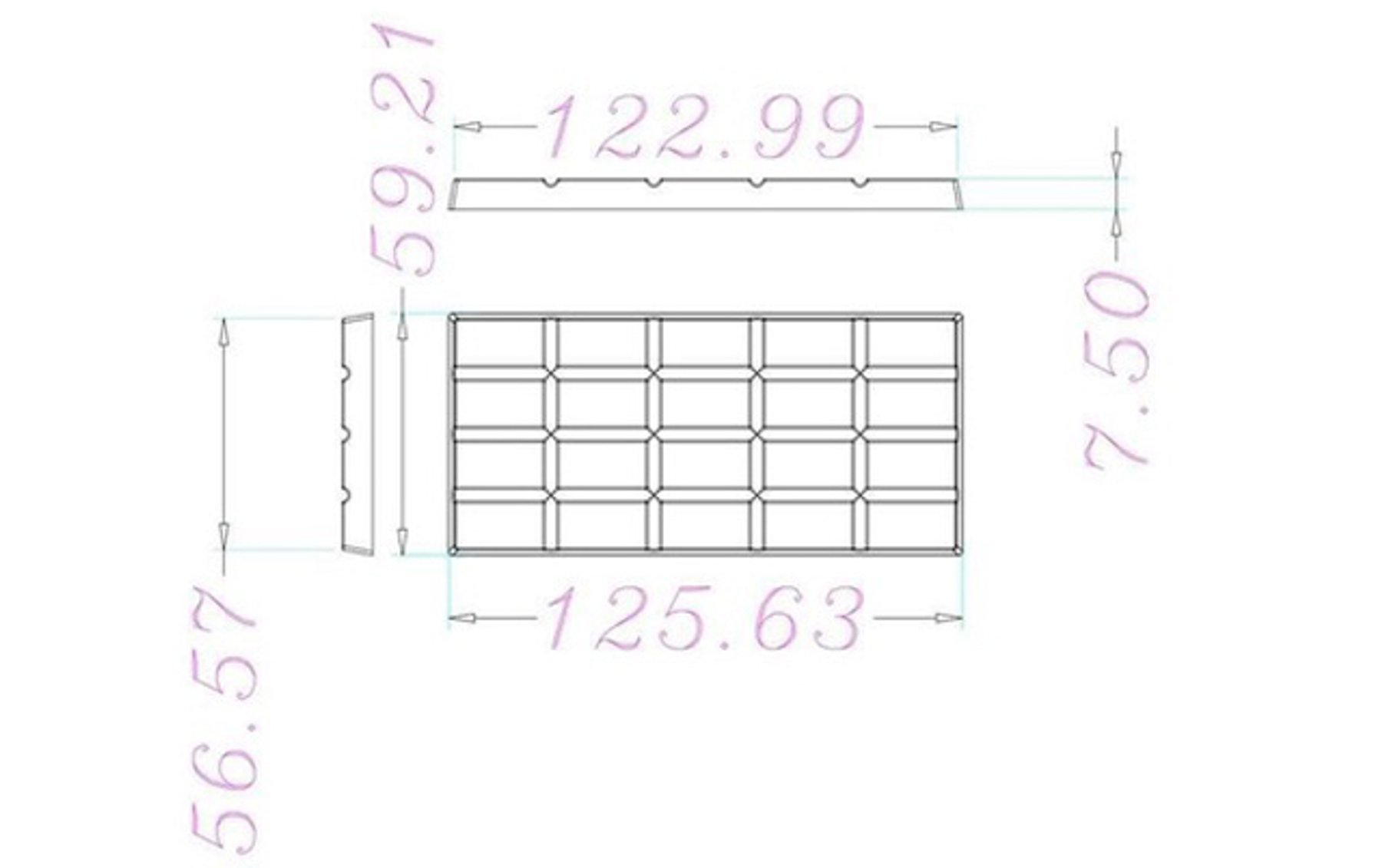

(The production weight per hour depends on the chocolate product that can be fit in one mould. One set of flow discharging plate is attached with the machine, design according to the mould shape)

Number of Moulds: recommended 350 pieces (NOT include in the machine price)

Moulds Size: 510*200*30mm

Machine Main Material: Stainless steel 201 machine frame and covers.Stainless steel 304 material hopper and depositing head

Machine Size: 16000*1000*1800mm,

Total Power: 25KW

Piston SeaI: Speedy

Hot Water Circulation Pump: Grundfos

Cooling system : one set of 15Hp refrigeration unit

Cooling System brand: Copeland -Emerson

Electrical Components: Siemens or Schneider or Omron brand

Motor/Reducer: Chinese brand

Pneumatic Air Cylinder: Air TAC

PLC: Delta

PLC control panel: Delta

Upgraded Components:

1 - All pumps upgraded to Durrex Lobe Pumps

2 - Installed 3-way valve at the tank before the pumps

3 - Heating pipe hoses were replaced with stainless steel mesh hoses

4 - Conveyor belt upgraded to PU blue belt

5 - Heating elements upgraded to 4×12kW per tank and heating pipe tanks

6 - Cooling tunnel upgraded to 20HP

7 - Heated pipe extended down to the hopper

8 - Power supply configured to 480V

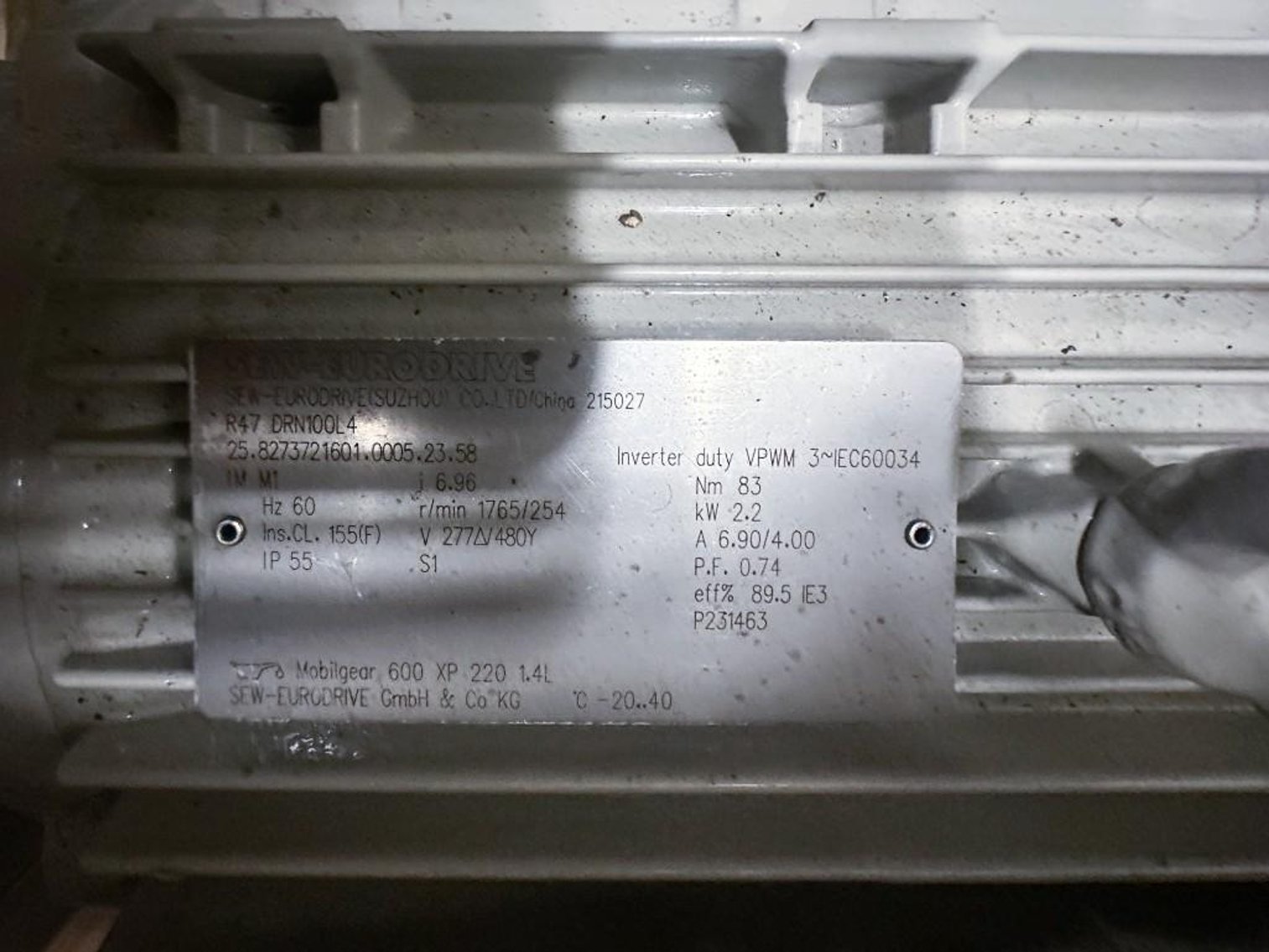

9 - Pumps controlled via VFD control system

10 - PLC control system upgraded to Siemens brand Motors upgraded to Siemens or WEG

11 - Servo motors and controllers upgraded to Siemens or Yaskawa (Japan)

12 - Cooling compressors upgraded to Danfoss or Copeland

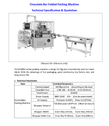

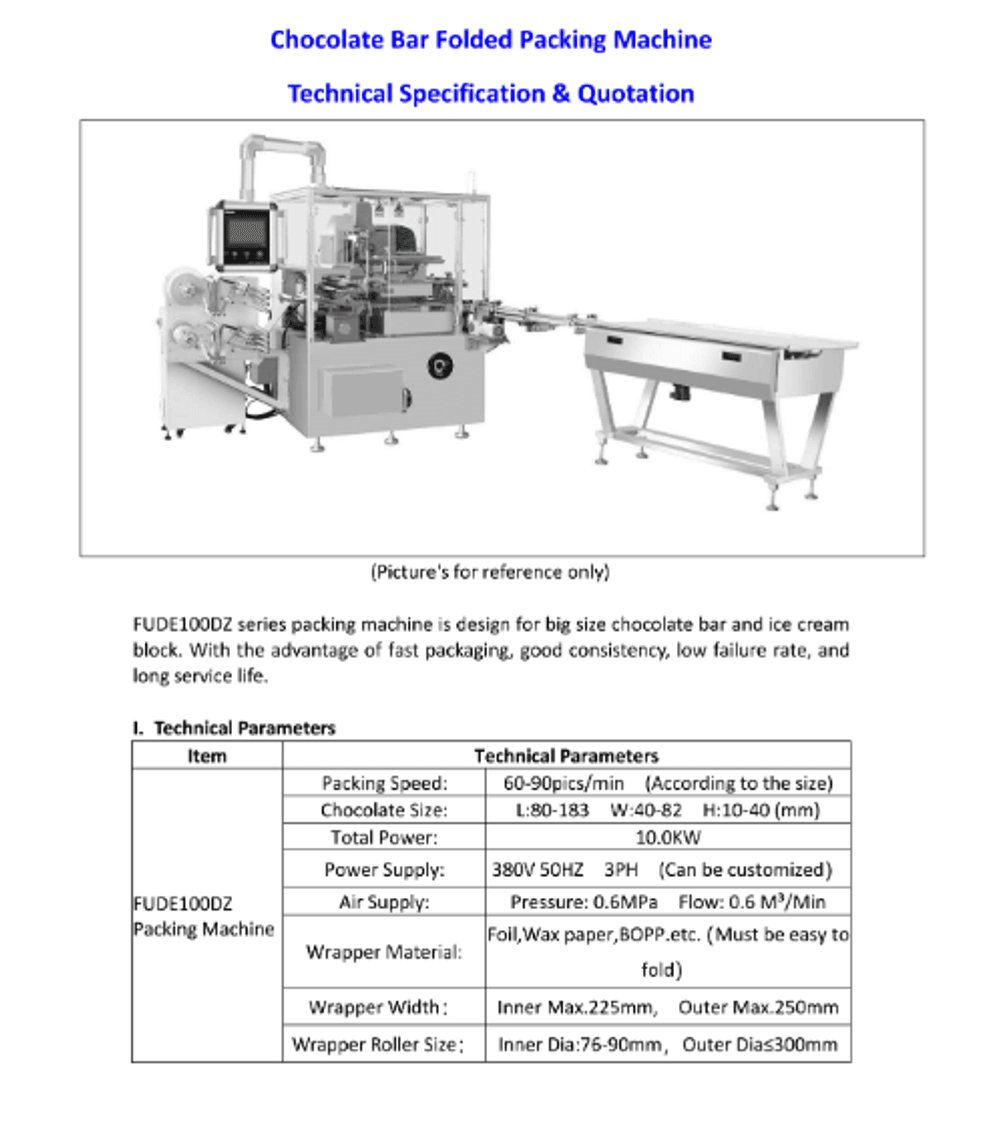

FUDE100DZ Chocolate Bar Folded Packing Machine

FUDElO0DZ series packing machine is design for big size chocolate bars and ice cream blocks. With the advantage of fast packaging, consistency, low failure rate, and long service life.

QUANTITY: 2

Model: FUDE100DZ

Packing Speed: 60–90 pcs/min (depending on product size)

Chocolate Size Range:

Length: 80–183 mm

Width: 40–82 mm

Height: 10–40 mm

Total Power: 10 kW

Power Supply: 380V, 50 Hz, 3 Phase

Air Supply: Pressure: 0.6 MPa Flow: 0.6 m³/min

Wrapper Material: Foil, wax paper, BOPP (must be easy to fold)

Wrapper Width: Inner Max: 225 mm Outer Max: 250 mm

Wrapper Roller Size: Inner Diameter: 76–90 mm Outer Diameter: 300 mm

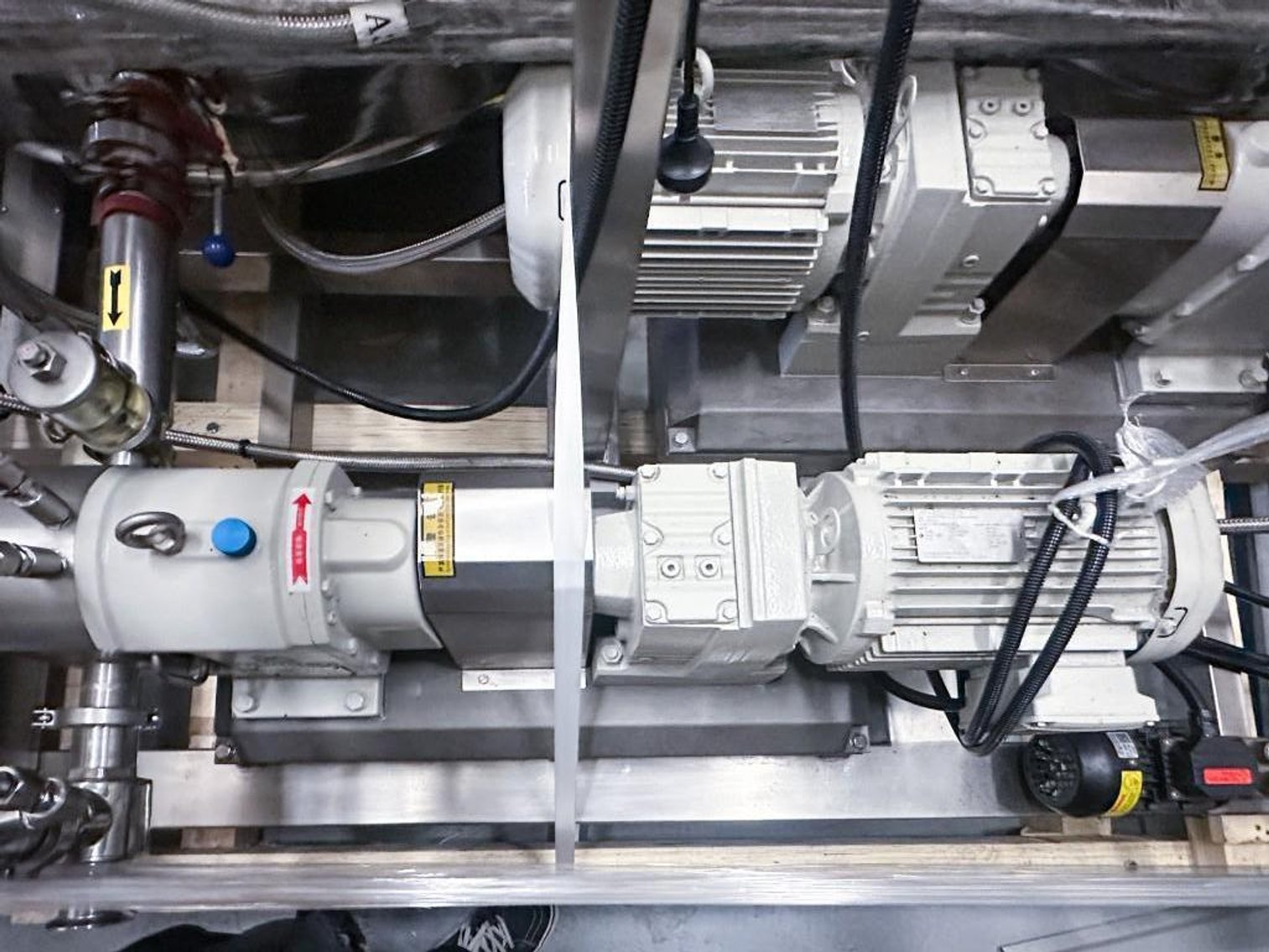

CBW500 Chocolate Storage Tank and pump skid with control panel

The CBW500 system offers continuous mixing, heating and feeding of chocolate product to the CJZ510-2 Dual-head depositor. It consists of 3 mixing tanks and 3 CCP25C-A product feeding pumps secured to one stainless steel skid platform. The system also has a dedicated control panel to manage the operation of the system.

QTY: 3 Tanks

Model: CBW500

Capacity: 500 L

Motor Power: 1.5 kW

Heating Power: 4 kW

Dimensions: Ø1000 × 1380 mm

Weight: 500 kg

Motor Brand: Siemens Electrical

Components: Siemens, Schneider, or Omron

All structural parts, including inner/outer cylinders, stirring blades, and covers, are made from stainless steel

CCP25C-A Product feeding pump

This pump is mainly used for transferring and conveying of chocolate pastes and other paste products. Series Y can also be used to convey chocolate pastes mixed with small granulated ingredients. This pump has circulating heat insulation.

Technical Parameters:

QTY: 3

flow rate: 25L/min

Delivery lift: 8m

Caliber: 1 inch

Power: 0. 7 .5 Kw

Weight: 80Kg

Dimensions:700*300*400mm

C: means gear Y: means leaves T: means Cam

Stainless steel 304 pump

Chinese brand motor

Location: San Diego, CA

Skidding and Loadout: TBD