Details

NEW – Process Kitchen System

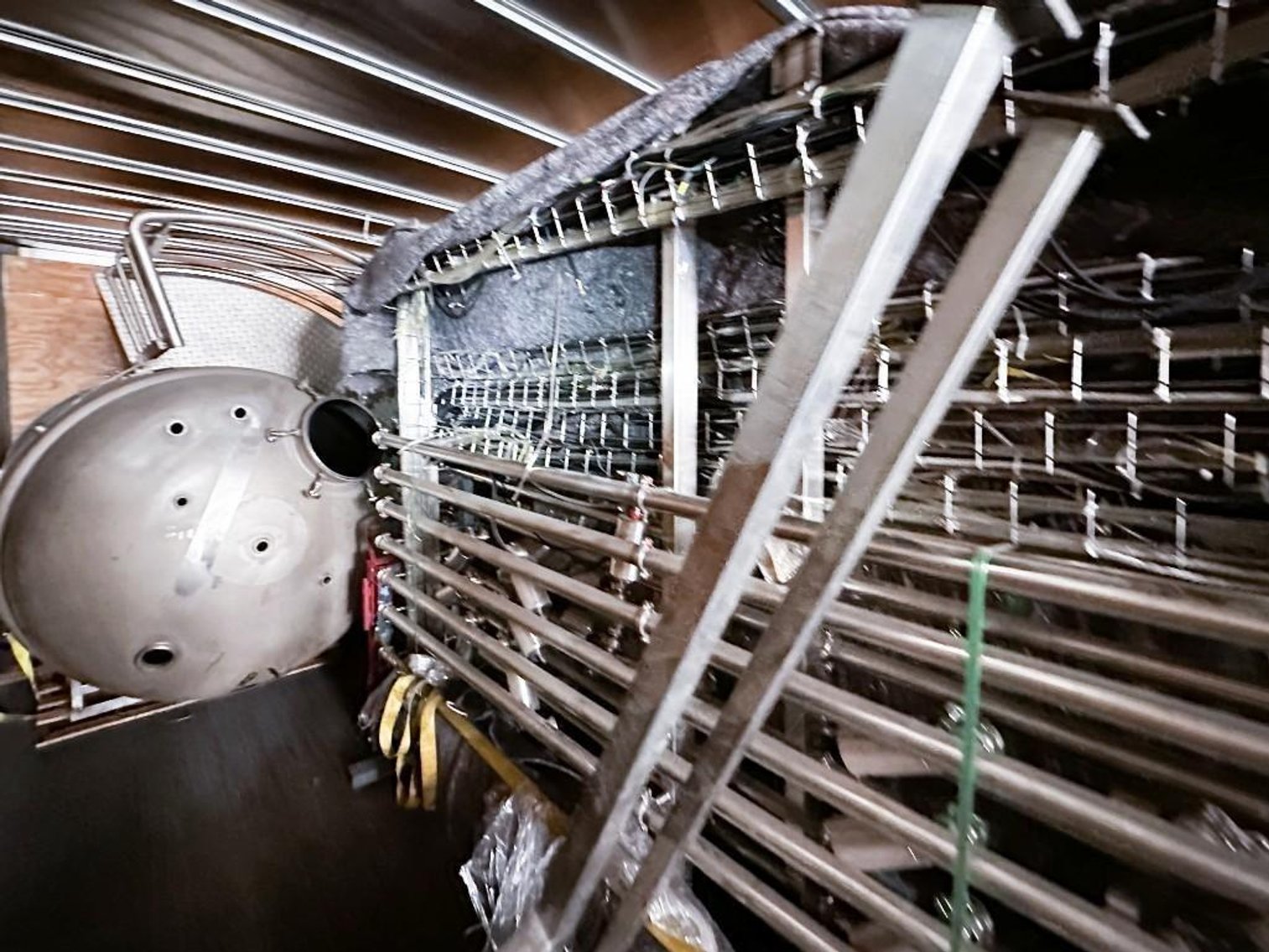

NEW – Stainless Steel Process Kitchen System suite designed for high-performance vacuum mixing and homogenizing applications. This system includes five fully jacketed mixing kettles, a mezzanine with integrated controls and sanitary piping, dual positive displacement pump systems, and homogenizer drives for bottom-mounted mixing motors.

Components:

Mixing Vessels (5 Total)

- 1 Large Kettle

- Capacity: 1500 Liters

- Construction: Stainless Steel, Fully Jacketed, Vacuum Capable

- Mixing Type: Dual Motion

- Features: 3” jacket, 2” bottom valve port with flow meter

- Dimensions:

- Outer Diameter: 56"

- Manhole Diameter: 15"

- Inside Diameter: 51"

- Inside Depth: 60"

- 2 Medium Kettles

- Capacity: 1000 Liters Each

- Type: Homogenizer Kettles

- Mixing: Triple Motion (Full Sweep, Dual Motion Blade)

- Configuration: No motors or drives on top; bottom port for homogenizing motor

- Dimensions:

- Tank Diameter: 42"

- Depth: 50" (Dish Bottom)

- Bottom Outlet Port: 2"

- Manhole: 15" Diameter

- 2 Small Kettles

- Capacity: 500 Liters Each

- Type: Homogenizer Kettles

- Mixing: Triple Motion (Full Sweep, Dual Motion Blade)

- Configuration: No motors or drives on top; bottom port for homogenizer, top port for mixing motor

- Dimensions:

- Tank Diameter: 34"

- Depth: 40" (Dish Bottom)

Pump Systems (2 Units)

- Durrex Positive Displacement Pumps

- Type: Tri-Lobe, Model 40TLS4-5C

- RPM: 324

- Manufacture Year: 2021

- Tri-Lobe Pumps by Yangzhou Lianhe Chemical Machinery Co.

- Model: ZB3A-20

- Speed: 400.5 RPM

- Flow Rate: 20L per 100 Revolutions

Mezzanine Platform

- Dimensions: 17 ft x 22 ft

- Features:

- Sanitary tubing rack with air actuators and butterfly valves

- 25-foot electrical conduit

- Handrails for safety and compliance

Skidding & Load-Out: Charges will be applied at prevailing market rates. Located in Los Angeles, CA