Details

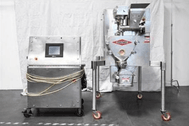

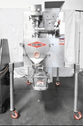

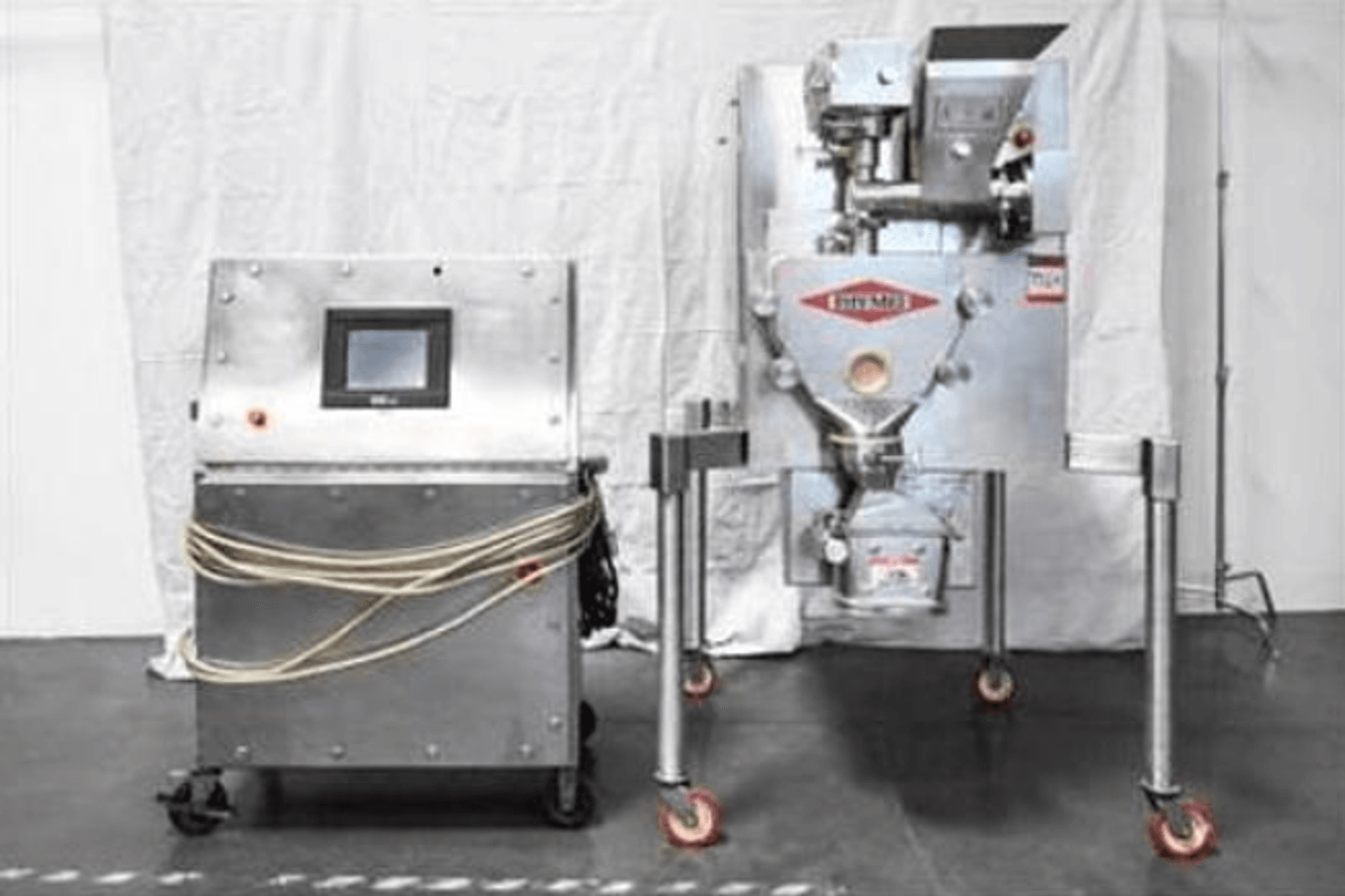

***SOLD*** 1 - Fitzpatrick FitzMill Comminutor M5A with Chilsonator IR520

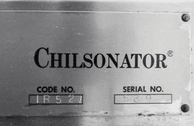

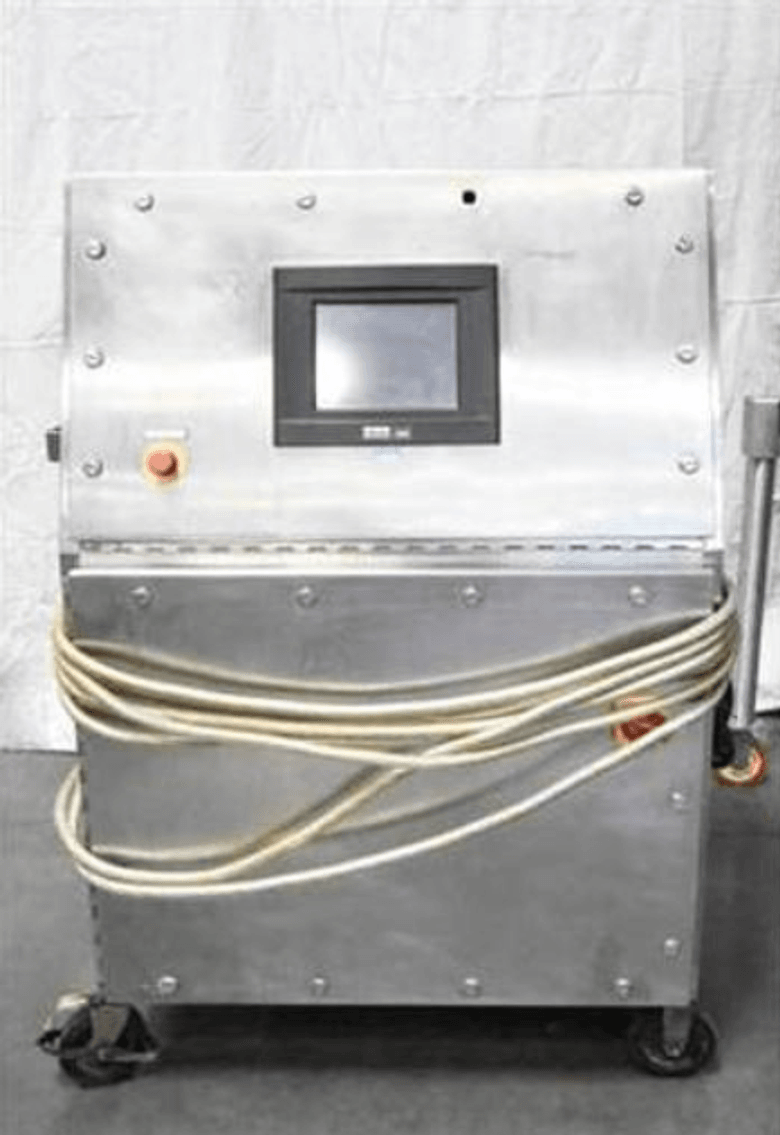

Chilsonator Model: IR520, Serial Number: 539

FitzMill Model: M5A, Serial Number: 1967

This system includes the Fitzpatrick FitzMill Comminutor M5A integrated with the Chilsonator IR520 roll compactor, offering a robust solution for dry granulation and precision particle size reduction.

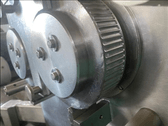

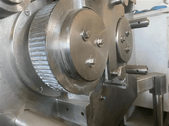

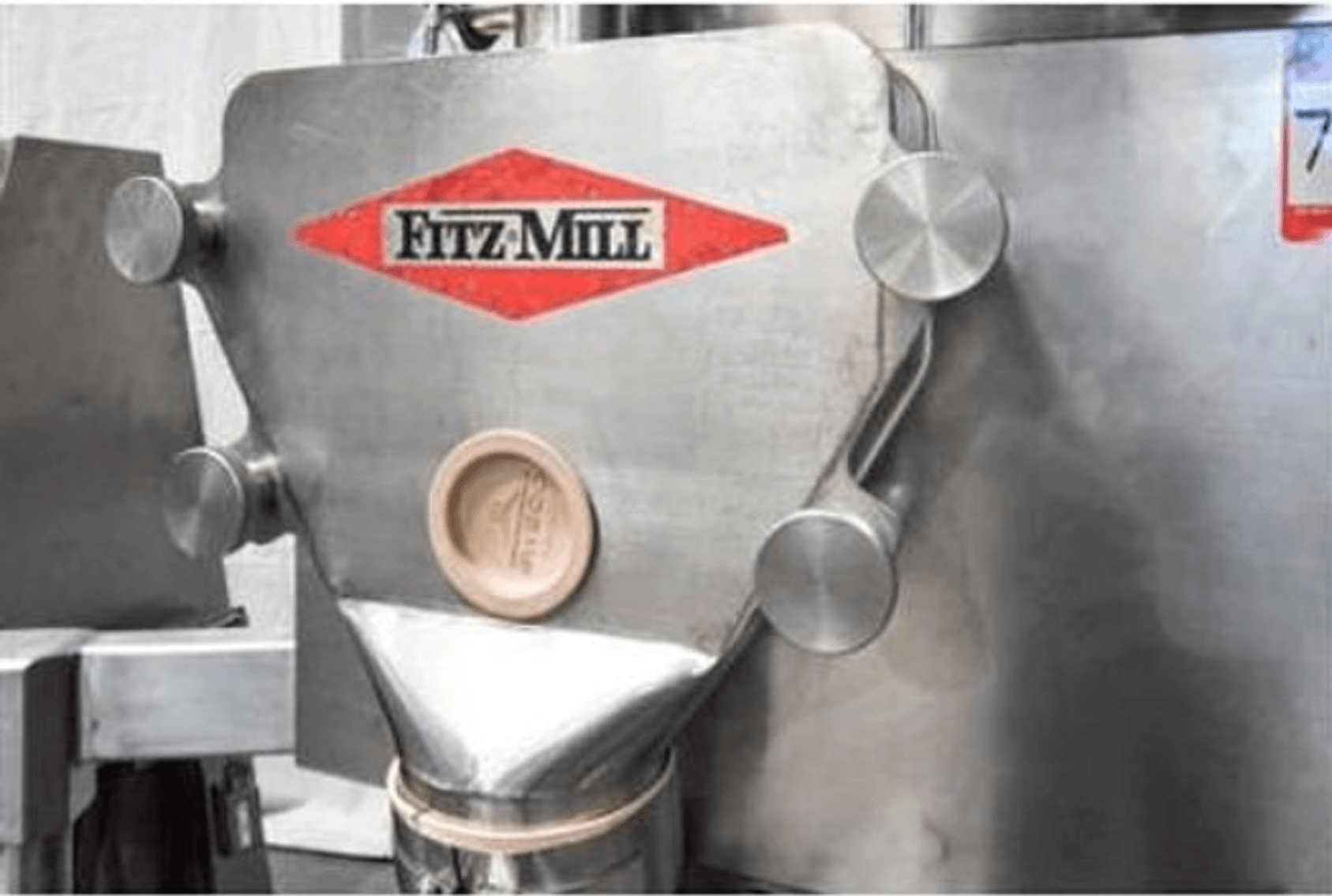

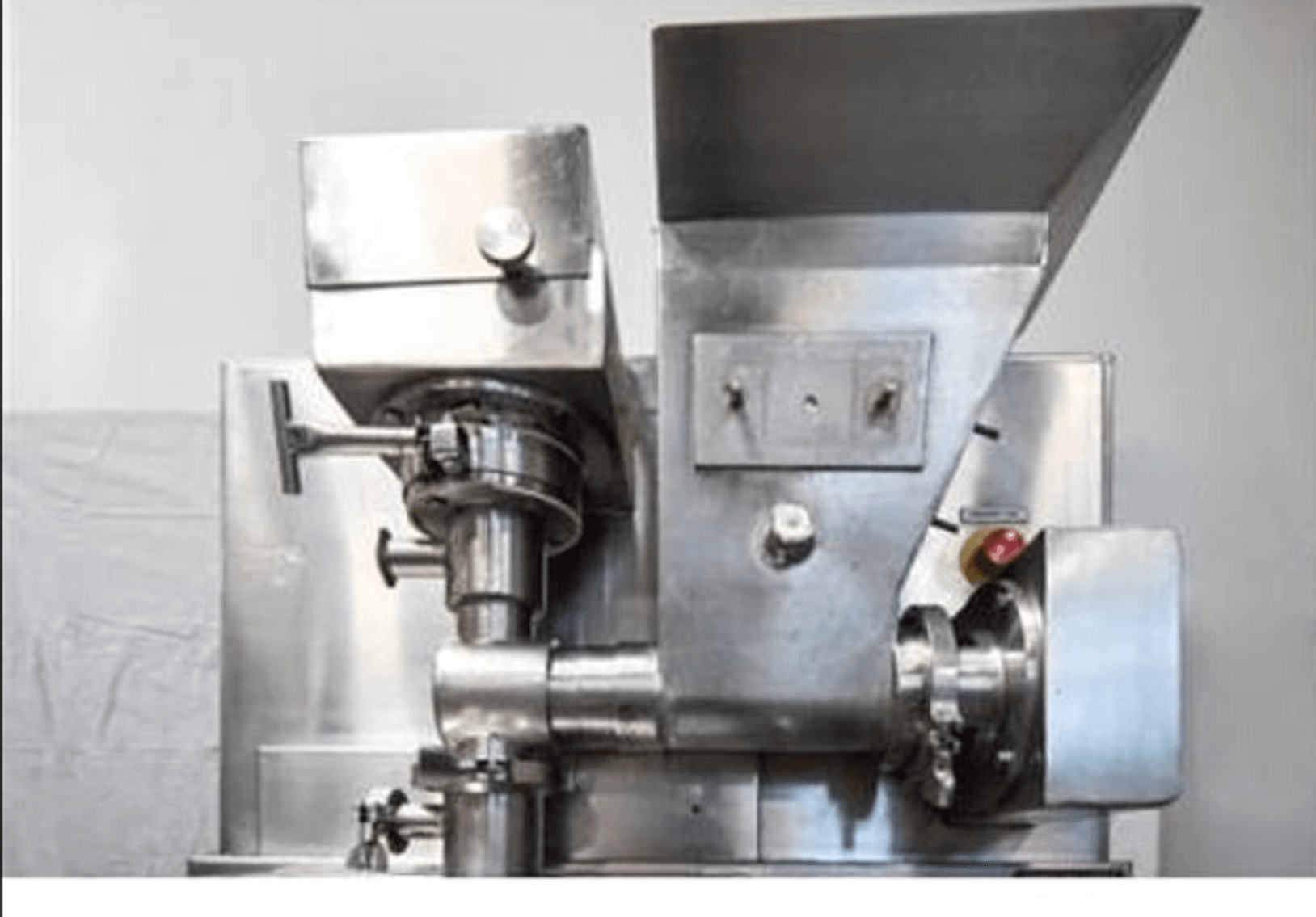

FitzMill M5A Comminutor

The FitzMill is globally recognized as the industry standard for high-performance particle size reduction. Suitable for batch or continuous processing, research, and product development, it delivers consistent and predictable results. Key features include a broad range of processing capabilities, predictable and reproducible particle size distribution, a compact and GMP-compliant design, and easy cleaning and maintenance. It also operates quietly with low heat and low dust generation, is scalable to larger production units, and supports optional containment solutions for toxic or potent compounds.

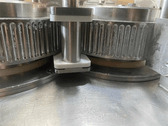

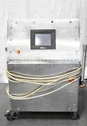

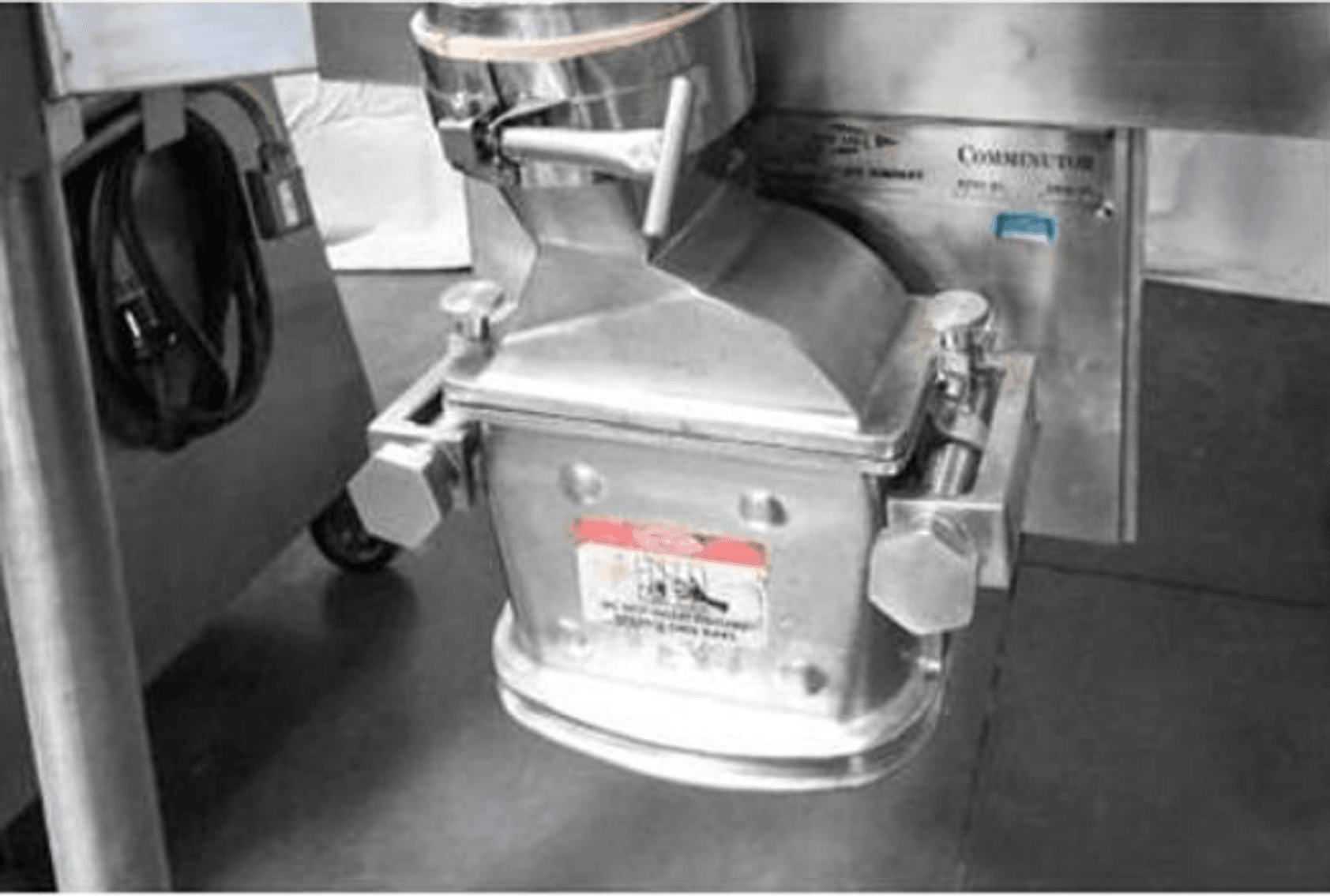

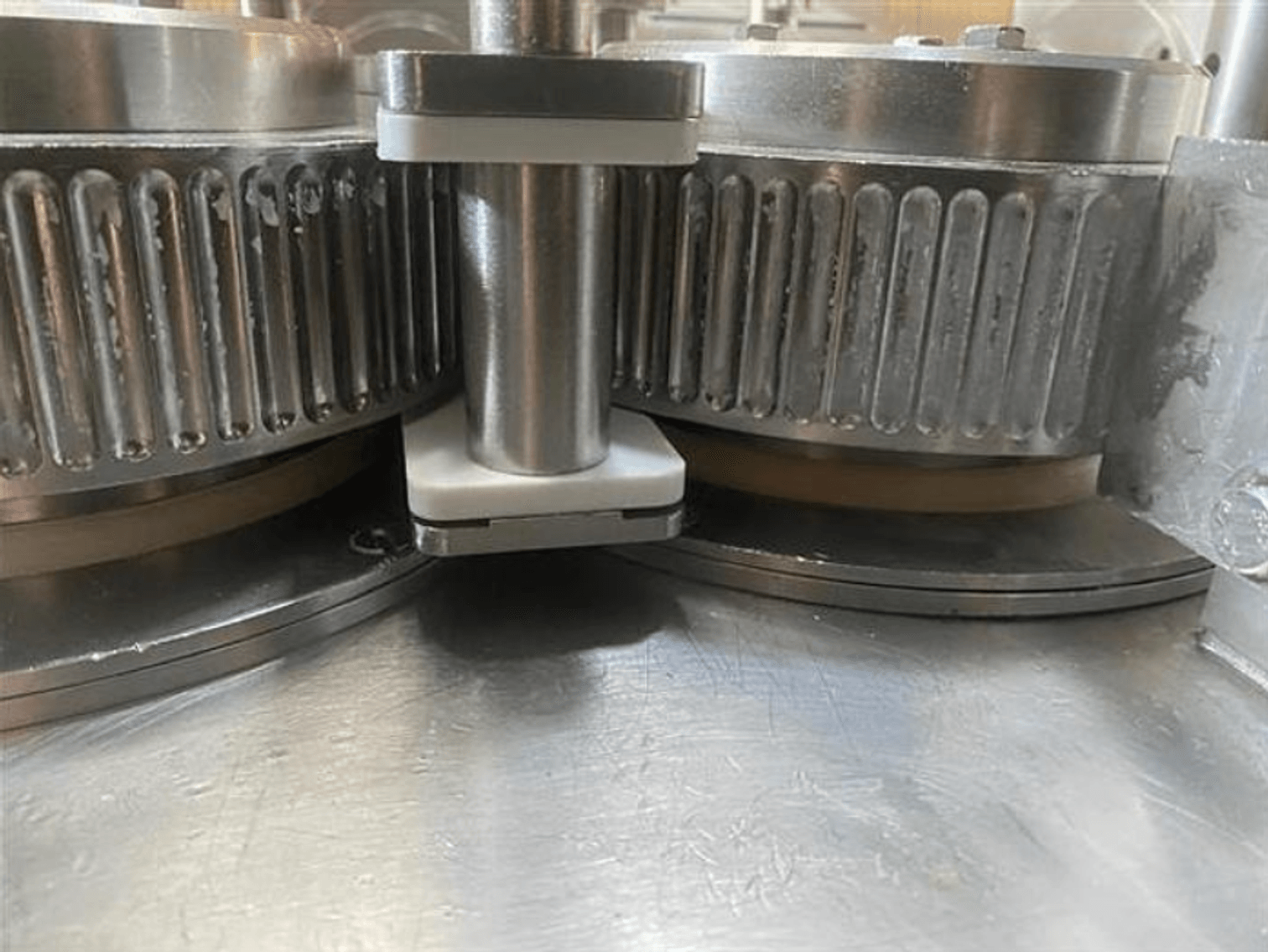

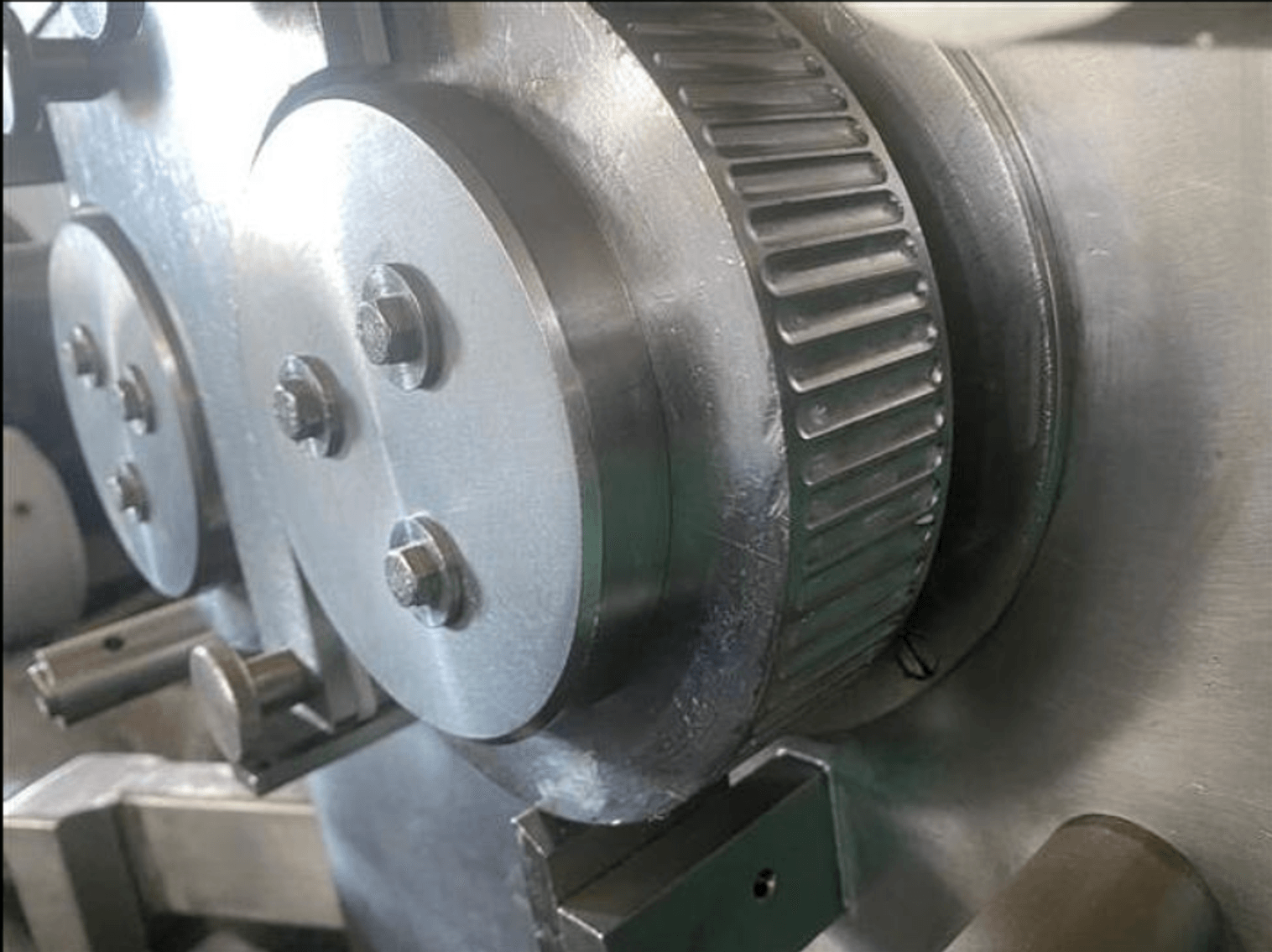

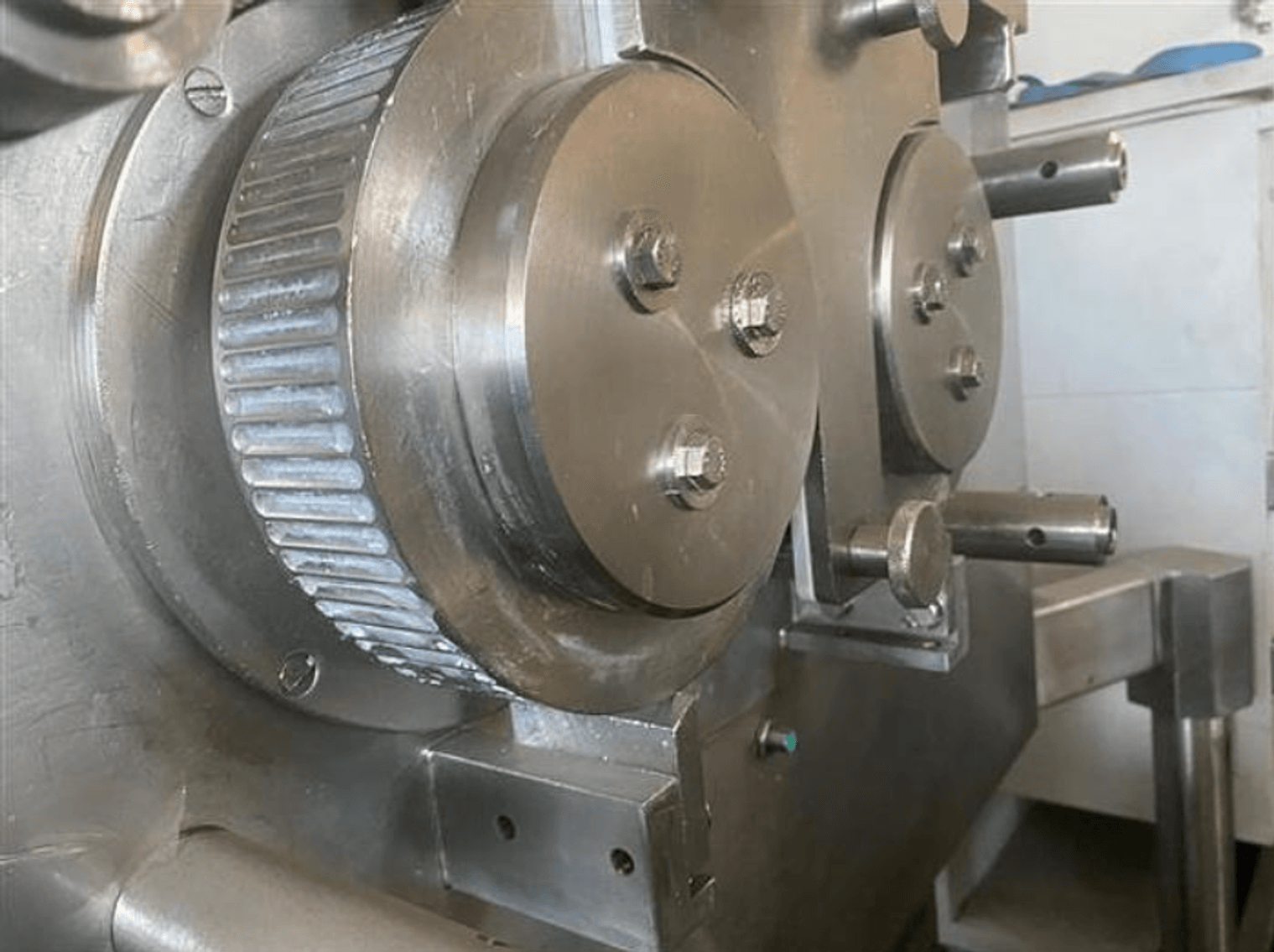

IR520 Chilsonator (Roll Compactor)

Designed for dry granulation, the Chilsonator transforms fine powders into free-flowing granules without the need for binders or solvents. It is ideal for preparing pharmaceutical blends for tableting, capsule filling, or further processing. Its key features include vertical and horizontal feed screws, efficient densification of active pharmaceutical ingredients and excipients, enhanced flow characteristics of powder blends, minimized product loss and dust generation, and suitability for handling sensitive, high-value materials.